Elephant Spring-Applied Brakes

Chain & Drive supplies a wide range of spring-applied brakes with braking forces up to 400,000 Newtons, with versatile applications within the mechanical engineering industry.

These systems have a wide range of use as holding brakes and emergency brakes that are locked by the spring when in a passive state. The release of the brake occurs hydraulically, pneumatically, or electrically. Examples of application are safety brakes in heavy industry, conveyor systems, all types of hoisting, and obviously in general mechanical engineering.

Spring applied brakes are usually released hydraulically, pneumatically or electrically.

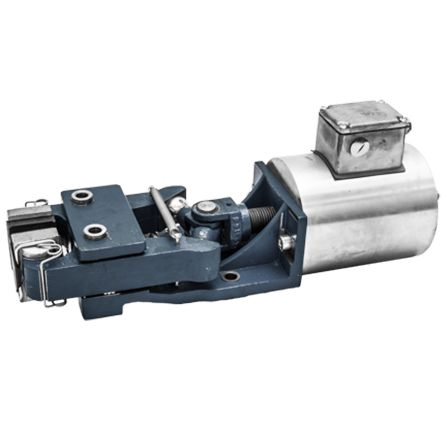

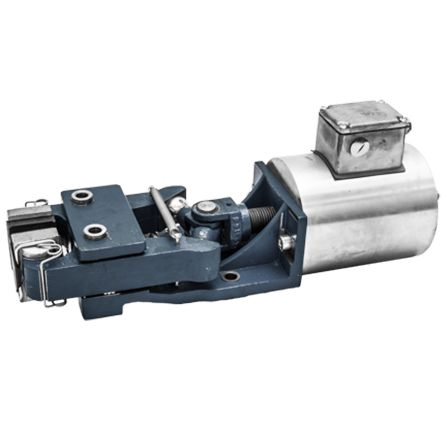

Spring-applied, electrically released

This spring-applied, electrically released brake calliper series impresses with its very simple design and easy handling. Ideal for cramped axial packaging space conditions and absolutely arbitrary installation positions. The EMS brake calliper can be deployed whether mechanisms such as compressed air and/or hydraulics are not available. Braking force 600 – 3000 N depending on the design.

Type EMS

Braking force up to 3,000 N

Size (mm): axial ~ 165; radial ~ 530 Mass (kg): 40

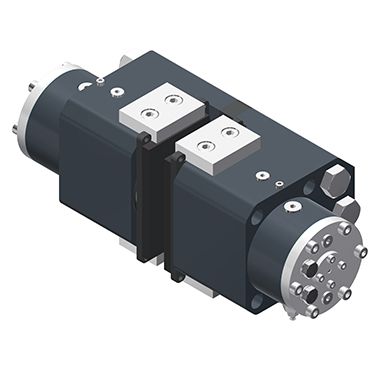

Spring-Applied, Hydraulically Released

These modular type EBS brakes has a reliable, robust and corrosion-protected design. Important aspects include durability, low maintenance and the virtually wear-free diaphragm springs. Additionally, the hydraulics can be completely overhauled or replaced while the calliper remains in place. Typical applications for this spring-applied, hydraulically released brake calliper include cranes, lifting gear and heavy industry.

Type EBS 001

Braking force up to 30,000 N

Size (mm): axial~397+T; radial~65 | Mass (kg): 46

Type EBS 002

Braking force up to 50,000 N

Size (mm): axial~473+B; radial~214 | Mass (kg): 90

Type EBS 004

Braking force up to 104,000 N

Size (mm): axial~569+B; radial~265 | Mass (kg): 190

Type EBS 006

Braking force up to 210,000 N

Size (mm): axial~743+B; radial~195 | Mass (kg): 495

Type EBS 008

Braking force up to 400,000 N

Size (mm): axial~812+B; radial~251 | Mass (kg): 735

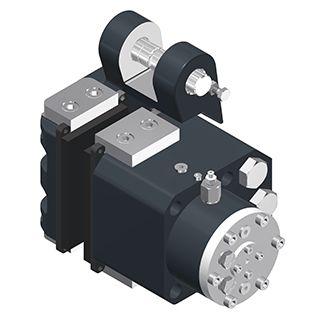

Floating Spring-Applied, Hydraulically Released

The floating versions of the EBS series are used for applications with limited installation space for a two-modular brake design or where economic interests are paramount. It has a device for air gap alignment to achieve an equal air gap between the brake disc and both of the brake pads. A wide range of applications for these systems are passive holding and emergency stop brakes, which are closed by the spring when not in use. Typical applications for this spring-operated, hydraulically opening brake calliper are cranes, hoists and heavy industry.

Type EBS 001 FL

Braking force up to 30,000 N

Size (mm): axial~295+T; radial~65 | Mass (kg): 40

Type EBS 002 FL

Braking force up to 50,000 N

Size (mm): axial~358+T; radial~87 | Mass (kg): 80

Type EBS 004 FL

Braking force up to 104,000 N

Size (mm): axial~435+T; radial~145 | Mass (kg): 185

Type EBS 006 FL

Braking force up to 180,000

Size (mm): axial~588+T; radial~195 | Mass (kg): 470

Type EBS 008 FL

Braking force up to 370,000 N

Size (mm): axial~643+T; radial~251 | Mass (kg): 815

Spring-Applied, Pneumatically Released

Spring-Applied, Pneumatically Released

R&H 200 CP Series

Braking force 3,000-8,000 N

Size (mm): axial ~ 295;

radial ~ 290 Mass (kg): 10.4-12

The spring-applied, pneumatically released brake calliper from the R&H 200 series is suitable for use as a holding or stopping brake. A pneumatic actuating pressure of 5 bar is required to open the brake. A mechanical, manual release option is integrated into the brake as standard. Braking force depending on the thruster size per calliper: 3,000 to 8,000 N. The brake’s finish makes it corrosion resistant, especially for outdoor applications or harsh environmental conditions. This corrosion protection is also possible for other brake types.

Spring-Applied, Pneumatically Released

Type R&H 250.412.01

Braking force up to 9.750 N

Size (mm): axial ~ 322;

radial ~ 300 Mass (kg): 14

The type 412 thruster offers a piston design without a diaphragm and is thus very durable. Complete release of the brake calliper is guaranteed at a pressure of 5 bar. The R&H 250.412.01 brake can be used both as an emergency stop and holding function brake in a variety of industries.

Spring-applied, Pneumatically released

Type R&H 350.435.01

Braking force 30,000 N

Size(mm): axial~435; radial~474 Mass (kg): 61,7

This reliable brake calliper offers easy assembly thanks to its lateral bolt-on ability. It is very robust and offers high braking forces. Thanks to the ability to use different spring-loads with the type 435 brake thruster, the R&H 350.435.01 can also be delivered with lower braking forces. Its main deployment areas are in the steel industry.

Aluminium Spring-applied, Pneumatically released

Type R&H 050.402.01

Braking force up to 1050 N

Size (mm): axial ~ 185; radial ~ 175 Mass (kg): 1,6

Due to the premium cast aluminium, the R&H 050.402.01 does not rust. The brake has a compact design and supports flexible assembly, as the thruster side can be replaced on demand. This brake calliper is used as an emergency stop and holding brake in all fields of general-purpose mechanical engineering.

Spring-Applied, Hydraulically Released

R&H 200 Series

braking force up to 10,400 N

Size (mm): axial ~ 305;

radial ~ 235 Mass (kg): 16

A safety brake with spring-applied, hydraulically ventilated thruster. The brake is used as an emergency stop and holding brake on high-powered plant. Actuating thrusters with various, and in some cases adjustable, spring forces are available.

Resources