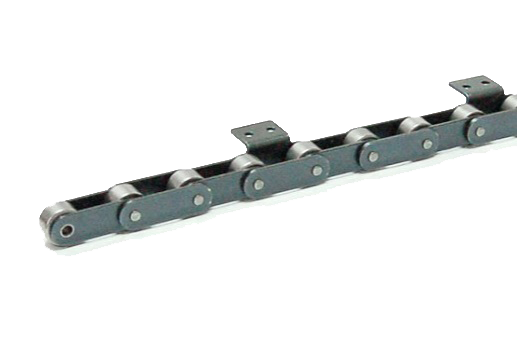

Engineered Conveyor Chain

Also called large pitch conveyor chain, these are designed for conveying materials or products on conveyor systems.

Engineered conveyor chains are designed for applications that require reliable and efficient material handling. These chains are engineered to withstand high loads, operate smoothly, and provide precise control over the movement of materials. They are commonly used in industries such as mining, manufacturing, packaging, food processing, and logistics. With their robust construction, advanced design features, and extensive range of configurations, conveyor and engineered chains ensure optimal performance and productivity in industrial material handling operations.

Chain & Drives conveyor chain range is manufactured for a variety of applications to BS, DIN and ISO standard specifications in breaking loads from 13kN (3,000lbf) to 900kN (203,000lbf) including metric and imperial pitch sizes. Solid bearing pin, hollow bearing pin, deep side plate, plain or flange rollers are just some of the chain varieties available.

Chains can be supplied in steel, stainless steel, nickel plated and with zinc sherardised anti-corrosion treatment. Pitch size from 38.1mm to 500mm. Stocks of common size chains and attachments are held in our stock.

We supply the complete range of ANSI, BS and DIN conveyor chains, attachment conveyor chain and specialised conveyor chain.

Featured Products

Type

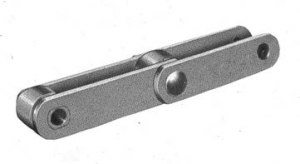

Hollow Pin Bearing Chain

The hollow bearing pin type chain facilitates fixing attachments to outer links by bolting through the hollow bearing pins and is suitable for use in all normal conditions. The attachments may be bolted up tight or held in the hollow bearing pin in a “free” manner. Bolted attachments should only span the outer link, as a bolted attachment spanning the inner link would impair the free articulation of the chain.

Deep Link Chain

Deep link-type chains have side plates with a greater depth than the normal chain plates; thus providing a continuous carrying edge above the roller periphery. When lateral flexing of the chain is required to negotiate horizontal bend radii, coned bearing pins are employed. Available in Hollow or Solid Pin versions.

Solid Bearing Pin Conveyor Chain

The solid bearing pin type chain, while having exactly the same gearing dimensions, i.e. pitch, inside width and roller diameter as the equivalent hollow bearing pin chain, is more robust and is recommended for use where arduous conditions may be encountered.

- BS Conveyor Chain

- ANSI Engineered Chain

- Rivetless Chain

- Detachable Chain

Resources