Rigid Couplings

Occasionally known as a sleeve, compression and flange coupling, the rigid coupling provides a solid connection between two shafts, for high precision and torque.

Rigid couplings are a mechanical coupling that connects two shafts without any flexibility or misalignment compensation, providing high precision and minimal backlash in torque transmission.

Rigid couplings are a reliable and cost-effective option for many industrial applications. Their high torque transmission, precision, simplicity, and zero backlash make them suitable for a wide range of applications, including machine tools, robotics, pumps, and other rotating equipment.

Types

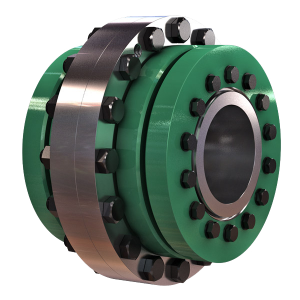

Flange Couplings

Flange couplings consist of two flanges that are bolted together to connect the shafts. They are commonly used in applications that require high torque transmission.

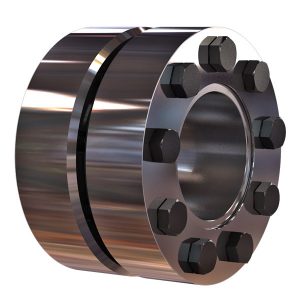

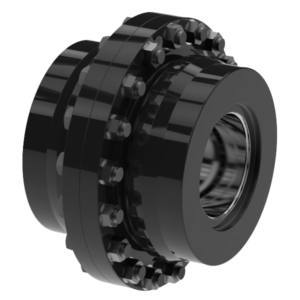

Clamp / Split-muff Couplings

Clamp couplings also called split-muff couplings consist of two separate halves that are clamped together around the shafts. They are typically used in applications where the shafts are difficult to align.

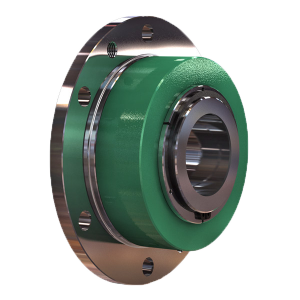

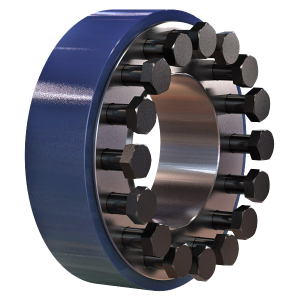

Compression Couplings

Compression couplings are designed to fit tightly on the shafts and are held in place by compressive forces. They are commonly used in applications where the shafts need to be disconnected frequently.

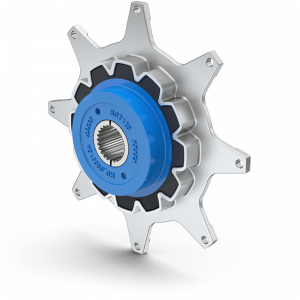

Keyless Couplings

Keyless couplings use a mechanical locking mechanism, such as a collet or a ring, to connect the shafts. They are commonly used in applications where the shafts need to be disconnected frequently.

Sleeve Coupling

Sleeve Couplings also called Muff Couplings or straight tooth couplings are the most common type of rigid coupling and consists of a solid cylindrical sleeve that connects two shafts. They are easy to install and require no special tools.

Tapered Couplings

Tapered couplings have a tapered shape and are designed to fit tightly on the shafts. They are commonly used in applications where the shafts need to be disconnected frequently.