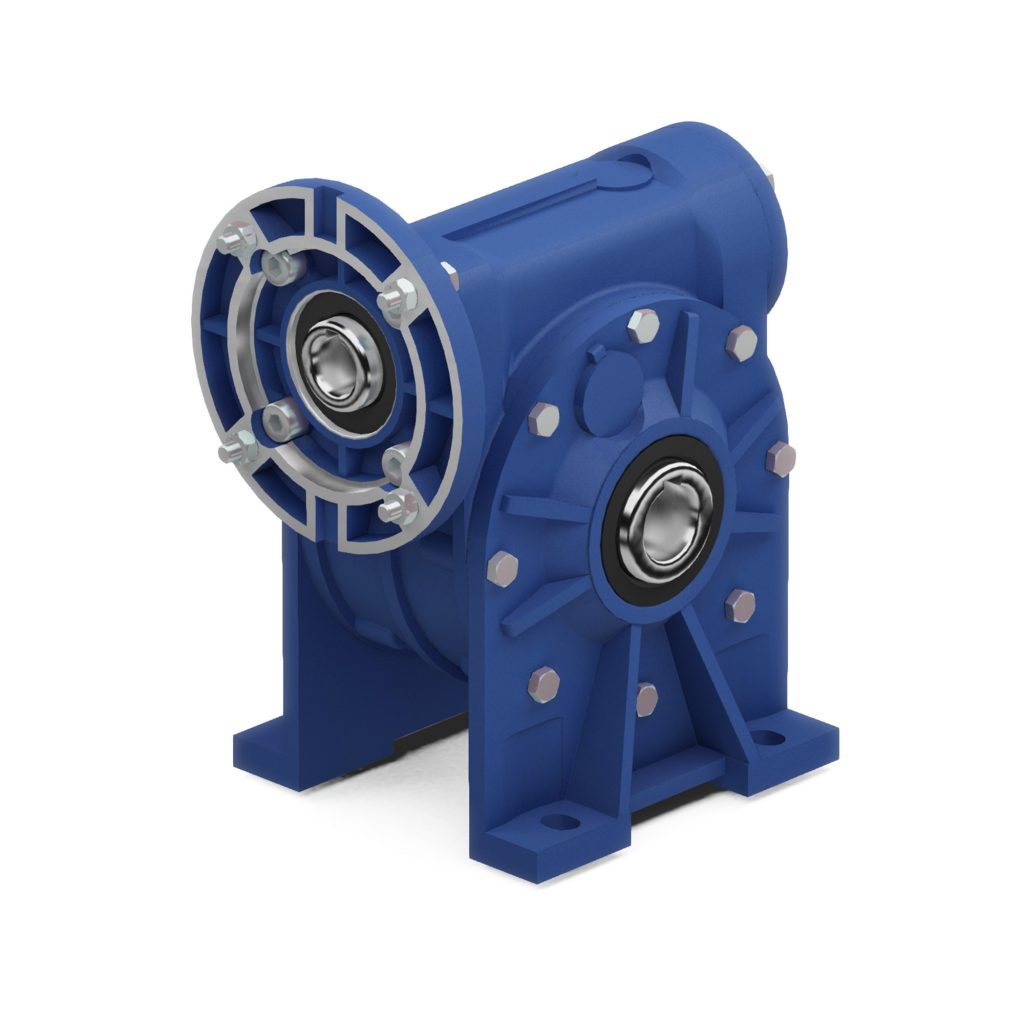

STM R Series Worm Gearboxes and Torque Limiter

The STM R Series Worm Gearboxes are a reliable and efficient solution for high performance gear reduction in a compact design. These gearboxes are part of STM’s standard line and are known for their versatility, making them suitable for a wide range of industrial and automotive applications.

STM R series, Worm Gearboxes and Torque Limiters have upgraded its main product with three new innovations: two technical and one commercial.

All aluminium components ranging from 28 to 70, are now die-cast for improved torsional resistance and structural flexibility. The ZI teething profile (section and involute) has been implemented to enhance efficiency and reduce noise. Additionally, a modular, attachable output flange (FL) has been added for increased versatility.

Always continuing to seek new ideas to expand the market reach – starting with the 1987 patent for the torque limiter integrated into our standard gearbox.

Key Features

- Hollow Bore Design: The hollow bore design allows for easy integration with shafts, facilitating versatile installation options in various machinery setups.

- High Gear Ratios: The R series offers a variety of gear ratios, providing significant torque multiplication while reducing speed. This makes them ideal for applications that require high power output with controlled operational speeds.

- Worm Gear Mechanism: Utilizing a worm gear design, the gearboxes ensure smooth operation, high efficiency, and minimal backlash, which is essential for precision applications.

- Compact and Lightweight: The R series gearboxes are designed to occupy minimal space while maintaining robust performance, making them suitable for environments where space is at a premium.

Performance Specifications

- Output Torque: These gearboxes are engineered to handle substantial output torque, making them suitable for demanding applications across various industries.

- Dynamic and Static Efficiency: The R series is optimised for both dynamic and static efficiency, ensuring minimal energy loss during operation and enhancing overall performance.

- Input Speed Compatibility: The gearboxes are designed to perform optimally at various input speeds, allowing them to adapt to different operational requirements.

Applications

The STM R Series Worm Gearboxes are versatile and can be used in:

- Industrial Machinery: Ideal for conveyors, mixers, and other machinery requiring reliable torque transmission.

- Automotive Systems: Perfect for automotive components where space and torque requirements are critical.

- Robotics and Automation: Their precision and reliability make them a great choice for robotic applications and automated systems.

Featured Products

Videos

Resources