Understanding Belt Length for Proper Selection for Belt-Driven Systems

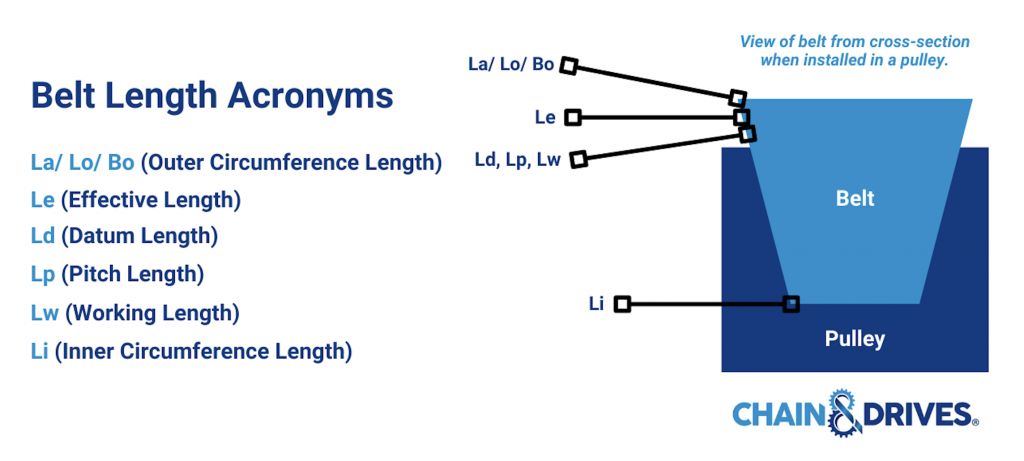

In the Australian industrial environment, understanding belt-length acronyms is crucial for the proper selection and maintenance of belt-driven systems. Different belt length measurements are used to describe various aspects of a belt’s geometry and its interaction with pulleys.

Here is a detailed discussion of the common belt-length acronyms and their meanings:

Belt Length Acronyms

La (Lo/ Bo): Outer Length

The outer length (La or sometimes referred to as Lo or Bo) refers to the physical circumference of the belt’s outer surface. This measurement is straightforward and is used primarily for belts where the outer dimension is critical for fitting into a specific space.

Li: Inner Length

The inner length (Li) is the physical circumference of the belt’s inner surface. This measurement is less commonly used but can be important for certain applications where the inner dimension affects the belt’s performance or fit.

Le: Effective Length

The effective length (Le) is the length around the neutral axis of the belt, which is the part of the belt that experiences neither tension nor compression during bending. This measurement is crucial for ensuring that the belt fits correctly & operates efficiently under load.

Ld: Datum Length

The datum length (Ld) is a standardised measurement often used for V-belts. It is close to the effective length and provides a reliable reference for comparing different belts & ensuring compatibility with pulleys & other system components.

Lp: Pitch Length

The pitch length (Lp) is used primarily for toothed belts, such as timing belts. It refers to the length of an imaginary line along the pitch circle of the belt, where the teeth are evenly spaced. This measurement is critical for ensuring that the belt meshes correctly with the teeth on the pulleys.

Lw: Working Length

The working length (Lw) is the length of the belt when it is under working tension. This measurement accounts for any stretch or deformation that occurs when the belt is in operation, ensuring that the belt maintains proper tension and alignment during use.

Application in the Australian Environment

In Australia, the proper selection & maintenance of belts are essential for various industries, including mining, agriculture, drilling, and manufacturing.

The following considerations are important:

Safety & Maintenance

- Power Down: Before any inspection, maintenance, or adjustment, ensure the machine is completely shut down and locked out to prevent accidental restarts.

- Right Belt for the System: Different belts, such as V-belts & Timing belts, have specific applications. Selecting the correct type is crucial for safety & efficiency.

- Safe Attire: Avoid loose clothing, jewelry & long hair that could get caught in moving parts.

- Safeguards: Never operate a belt-driven system with guards removed or bypassed.

- Regular Inspection: Regularly inspect belts & Pulleys for wear & tear, maintaining proper tension and alignment as specified by the manufacturer.

- Cleanliness: Keep the area around belt drives free of debris & clutter that could cause a fire hazard or become caught in the belt system.

Environmental Considerations

- Temperature & Humidity: Proper storage conditions are vital to prevent premature wear. Belts should be stored at temperatures below 29.5˚C & relative humidity below 70% to avoid fungus or mildew formation.

- Special Applications: In environments with flammable substances, fire-resistant anti-static (FRAS) belts may be necessary. Heat-resistant & oil-resistant belts are also available for specific industrial applications.

By understanding these belt-length acronyms and their correct applications, you can ensure the efficient & safe operation of belt-driven systems. Proper selection, maintenance, and storage of belts are essential to maximise their lifespan & performance in various Australian industrial environments.

Chain & Drives is ready to assist you & your team with your Industrial Belt requirements utilising our large range of products & knowledge to help improve your application productivity.

For more details on our Product Range – call us or email support@chainanddrives.com.au

We offer virtual demonstrations & onsite customer meetings.