The Hidden Cost of Coupling Misalignment

How the Right Coupling Protects Your Equipment and Reduces Downtime.

What Is Coupling Misalignment?

Misalignment in rotating machinery is a common but often overlooked cause of premature wear, unexpected downtime, and increased energy use. Even when equipment is correctly aligned at installation, everyday operation can shift shafts out of position. Thermal changes, foundation movement, and normal component wear all contribute to misalignment, which, if left unmanaged, stresses connected equipment and drives up maintenance costs.

Understanding the types of misalignment and how the right coupling can accommodate them is essential for reliable operation and lower total cost of ownership.

Understanding the Types of Misalignment

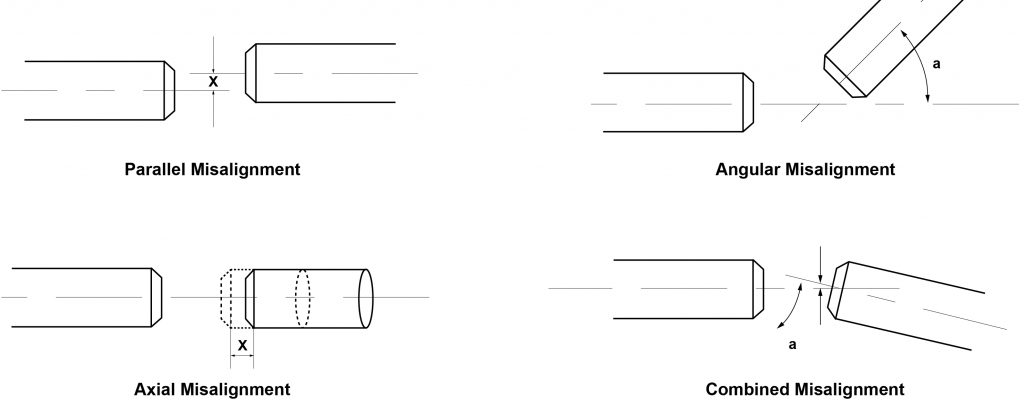

Parallel (Offset) Misalignment

Occurs when shafts experience shear displacement and no longer share the same rotational centreline.

In real-world applications, it is common to see a combination of all three types simultaneously.

Angular Misalignment

Caused by bending, where shafts meet at an angle rather than running in a straight line.

Axial Misalignment

Caused by bending, where shafts meet at an angle rather than running in a straight line.

Combined Misalignment

Occurs when angular, parallel and axial misalignment happen at the same time.

This is common in real operating conditions and places increased stress on connected components.

Why Misalignment Develops Over Time

Even well-installed equipment will experience movement throughout its service life. Common causes include:

- Thermal growth during operation

- Foundation settling or structural movement

- Pipe strain transferring loads into machinery

- Bearing wear

- General equipment settling

Conventional couplings often struggle to tolerate these changes, particularly when misalignment gradually increases.

The Impact of Misalignment

Misalignment may seem minor, but its effects can ripple through the system:

- Increased loads on bearings and seals

- Shortened life for motors, pumps, and gearboxes

- Higher energy consumption due to friction and vibration

- Frequent maintenance or unplanned shutdowns

These costs often go unnoticed because they are absorbed into general maintenance or downtime, rather than being traced back to the coupling itself.

How Proper Coupling Design Can Help

A coupling designed to tolerate misalignment can protect connected equipment and reduce overall stress. Key features include:

- Ability to handle angular, axial, and parallel misalignment without transferring excessive forces

- Non-metallic contact surfaces to prevent wear, fretting, and backlash

- Reliable performance even as operational conditions change

- Reduced vibration, helping to extend component life and improve efficiency

Choosing the right coupling allows equipment to continue operating safely even as misalignment develops over time.

In Summary

Misalignment is unavoidable in real operating environments. Damage, downtime and rising maintenance costs do not have to be.

Selecting a coupling designed to manage misalignment — rather than resist it — can significantly improve reliability, extend equipment life and reduce overall operating costs.

Related Products