How to Measure Industrial Timing Belts

Accurately measure your synchronous timing belt to ensure the correct fit, reliable performance, and reduced downtime.

Accurate measurement of synchronous timing belts is essential for correct replacement, reliable performance, and longer component life. This guide helps you identify a belt’s key dimensions so you can confidently order the right belt for your machine.

What Is a Timing / Synchronous Belt?

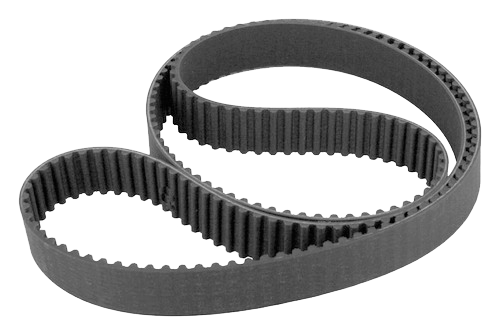

A timing belt — also called a synchronous belt — has teeth that engage mating pulleys to prevent slippage.

Unlike V-belts that run on smooth pulleys, timing belts require toothed pulleys that match the belt’s tooth profile.

Even if the belt markings are worn or hidden, you can determine its specifications manually with the right measurements.

Key Measurements You Need

Tooth Profile

The tooth profile defines how the belt engages with the pulley and is crucial for fit and performance.

Pitch:

- This is the centre-to-centre distance between adjacent teeth.

- Use metric units (millimetres) where possible — or clearly state imperial measurements if that’s what you have.

Tooth Shape:

- Shapes vary from rounded to trapezoidal forms.

- Metric belts often have rounder teeth; imperial profiles are typically more trapezoidal.

Thickness:

- Measuring the belt’s thickness can help confirm its profile but may be affected by wear.

Pitch Length

Pitch length is the total length of the belt measured along the pitch line — essentially the length around the belt’s mid-tooth circle.

- To calculate: Pitch × number of teeth = pitch length.

- Example: A belt with a 10 mm pitch and 32 teeth has a 320 mm pitch length.

Counting Tips:

- Mark a starting tooth.

- Consider marking every tenth tooth to avoid miscounts.

Width

Measuring width is straightforward using a ruler or caliper — just ensure the belt isn’t excessively worn.

- Width is measured across the belt’s body, perpendicular to its length.

Other Factors to Confirm

Besides the three key values above, consider the following before ordering:

- Application use case: Heavy-duty drives may need stronger belts.

- Material of the belt: Rubber, polyurethane, aramid or high-performance composites can affect durability.

- Pulley markings: If accessible, pulleys sometimes list the belt profile.

Related Products