Track Chain & Components

Chain & Drives offers a wide range of alternative Undercarriage products to suit major equipment manufactures and track chain installations used for shuttle conveyors and apron feeders on sites across Australia.

Our range of products offers an efficient, reliable and economical alternative solution to any operation. Whether in open pit mining, quarrying or earthmoving of large land reclamation, we can offer you the right answer to your undercarriage needs.

We supply Special heavy duty DTC Squeaky and sealed and lubricated track chains that have been accurately designed for increased pin and bush retention. The links incorporate greater pin to link and bush to link contact areas, while additional link wear material increased contact life.

- The Complete Choice – Our range of products offers an efficient, reliable and economical alternative solution to any operation. Whether in open pit mining, quarrying or earthmoving of large land reclamation, we can offer you the right answer to your undercarriage needs.

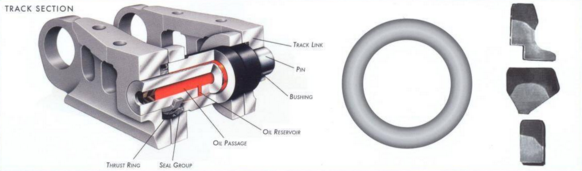

- Track Chains – Special heavy duty DTC Squeaky and sealed and lubricated track chains have been accurately designed for increased pin and bush retention. The links incorporate greater pin to link and bush to link contact areas, while additional link wear material increased contact life.

- Rollers – Rollers feature reinforced flanges and have been designed and manufactured to achieve longer life in the most severe applications.

- Idler Groups – Track idler groups are manufactured for superior wear resistance where the cast, forged or fabricated idlers provide superior structural support.

- Track Shoes – A range of forged shoes have been developed. A fully automated forging line, equipped with a 32,000 tonne press followed by machining and a heat treatment process deliver a product with the greatest mechanical wear resistant properties

- Forged Links – Our links are forged from Boron Steel, quenched, tempered and induction hardened using the latest automated link hardening equipment to ensure excellent wear resistance under even the most severe working conditions.

- Links – Our links are designed using the latest CAD systems to maximize the contact surface between pins and busings and are machined to precise tolerances to ensure perfect fit and sealing. Rail hardness is > Rockwell C50 with a case hardness depth up to 12 mm. depth depending on link size. Core Hardness is > Rockwell C 32.

- Split Links are profiled according to the latest OE design using “State of the Art” EDM wire cutting technology.

- Pins & Bushings – Pins and bushings are critical to track chain wear life and are manufactured and dimensionally matched to ensure a perfect fit and sealing and joint integrity. Outside Surface Hardness is > Rockwell C58 to a depth of > 4 mm. with a core hardness of > Rockwell C34.

- Bushings – The surface hardness of the Track Bushing is critical for uniform wear resistance and long life. Out Bushings have a surface Hardness of Rockwell C55, to a depth exceeding 3.5 mm. The inner Bore surface is hardened to a Rockwell C53 to a depth exceeding 3.5mm.

- Chain Assembly – Lubricated Chains are assembled on fully automated chain assembly lines. Seal installation, Plug introduction and Oil fill quantities are 100% computer controlled and every joint is individually pressure tested to eliminate the possibility of leakage during working conditions.

- Min/Max interference fit tolerances between the Pins, Bushings and Links are maintained automatically by min/max Press force specifications. This process minimises link breakage and pin/bushing drifting.

- Custom Assembled Track Groups – We will custom assemble track groups with a wide variety of track shoe designs upon request.