Cam Followers

Cam followers are specialised bearings designed to follow cams or tracks on the outer surface, allowing for smooth and precise motion in applications like cam mechanisms, conveyor systems, and track systems.

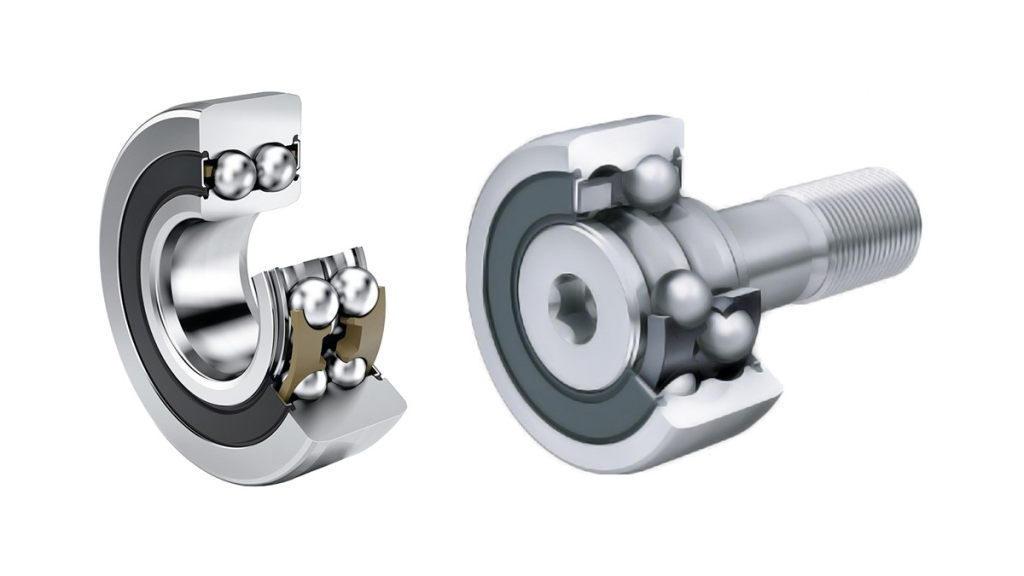

Ball Bearing Track Rollers

Ball bearing track rollers are self-retaining, single or double-row ball bearings with particularly thick-walled outer rings. In addition to high radial forces, these bearings can also support axial forces in both directions.

Features & Benefits

- Ready-to-fit, single or double row rolling bearings based on deep groove or angular contact ball bearings

- Supplied with or without a stud (designs without a stud are mounted on shafts or studs)

- Have particularly thick-walled outer rings with a crowned or cylindrical outside surface

- Supports high radial loads

- Tolerates axial loads which are due to small misalignment defects, skewed running or temporary contact running impacts

- Sealed on both sides

- Also available with a plastic tyre on the outer ring for low-noise running

- Not mounted in a housing bore, but are supported on a flat mating track

- Can be adjusted to the mating track in the design with the eccentric collar, thus permitting, for example, larger manufacturing tolerances in the adjacent construction

Yoke and Stud type Roller Bearing Track Rollers

Yoke-type track rollers are single or double-row units mounted on shafts or studs. They comprise thick-walled outer rings with a profiled outside surface and needle roller and cage assemblies or full-complement rolling element sets.

Features & Benefits

- Ready-to-fit needle or cylindrical roller bearings of single or double row design

- Mounted on shafts or studs (yoke type track rollers) or supplied with a heavy-section roller stud with fixing thread and a mounting aid (stud type track rollers)

- Have particularly thick-walled outer rings with a crowned outside surface

- Supports high radial loads

- Tolerates axial loads which are due to small misalignment defects, skewed running or temporary contact running impacts

- Available with or without an inner ring (yoke type track rollers)

- Produced with or without axial guidance of the outer ring (stud type track rollers are always produced with axial guidance)

- Open or sealed on both sides

- Not mounted in a housing bore, but are supported on a flat mating track

- Can be adjusted to the mating track in the design with the eccentric collar, thus permitting, for example, larger manufacturing tolerances in the adjacent construction

Cam Rollers

Cam rollers are similar in their construction to single and double-row support rollers, except that the raceway is formed by a heavy-section roller stud with a fixing thread and lubrication hole. Cam rollers are often used for transmitting high radial loads. X-life quality PWKR cam rollers from INA now boast an even greater level of performance.

Features & Benefits

- Up to 30% higher static and dynamic load carrying capacity due to optimized raceway geometry

- Higher permissible ring load by changing the material of the outer rings

- Improved outside surface quality by optimizing the surface structure

- Increased protection against corrosion due to Corrotect® coating

Proven application areas for these products include cam mechanisms, guideways, conveying systems and linear guidance systems.

Backup Rollers

Backup rollers are often used for transmitting high radial loads. X-life quality PWTR backup rollers from INA now boast an even greater level of performance.

Features & Benefits

- Up to 30% higher static and dynamic load-carrying capacity due to optimized raceway geometry

- Higher permissible ring load by changing the material of the outer rings

- Improved outside surface quality by optimizing the surface structure

- Increased protection against corrosion due to Corrotect coating

Variants of track rollers, backup rollers and cam rollers include:

- Track rollers X-life

- Stud-type track rollers

- Backup rollers X-life

- Cam rollers X-life