Transfluid K Series Fluid Couplings

A dynamic constant fill design with dual-functionality. It integrates a driving impeller (pump) on the input shaft, a driven impeller (turbine) on the output shaft, and a sealed cover flanged to the outer impeller.

The TRANSFLUID K Series Fluid coupling functions as a hydrodynamic transmission, where impellers act as both a centrifugal pump and a hydraulic turbine. When an input drive powers the pump (like an electric motor or Diesel engine), it transfers kinetic energy to the oil within the coupling. Centrifugal force then propels the oil across the pump blades outward in the coupling.

Benefits

- very smooth start-ups

- protection of the motor and the driven machine from jams and overloads use

- higher duration and operating convenience of the whole drive train, thanks to the protection function achieved by the fluid coupling

- higher energy saving, thanks to current peak reduction

- limited starting torque down to 120% in the versions with a double delayed fill chamber

- same torque at input and output: the motor can supply the maximum torque even when load is jammed

- torsional vibration absorption for internal combustion engines, thanks to the presence of a fluid as a power transmission element

- possibility to achieve a high number of start-ups, also with an inversion of the rotation direction

- load balancing in case of a double motor drive: fluid couplings automatically adjust load speed to the motors speed

- high efficiency

- minimum maintenance

- cast iron and steel material with anticorrosion treatment

Applications

- Belt Conveyors

- Crushers and Screens

- Fans and Blowers

- Pumps

- Mixers and Agitators

- Industrial Dryers

- Bucket Elevators

- Centrifuges

- Extruders

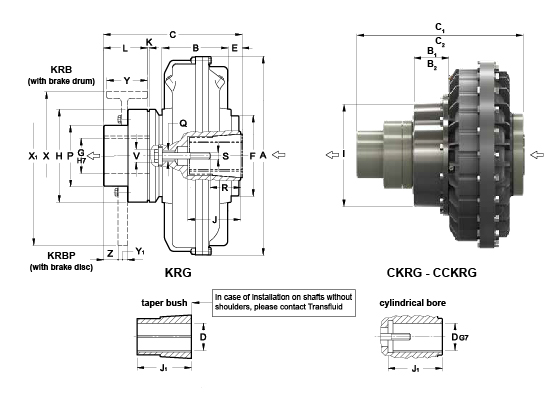

SERIES 7: KRG – KRB (w/Brake Drum) – KRBP (w/Brake Disc) / CKRG – CCKRG

| D | J | J1 | A | B KR… | B1 CKR… | B2 CCKR… | C KRG | C1 CKRG | C2 CCKRG | E | F | G max | H | I | K | L | P | Q | R | S | V | Z | Flex coupling | brake drum X – Y | brake disc X1 – Y1 | Weight kg (without oil) | Oil max (l) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| KRG | CKRG | CCKRG | KRG | CKRG | CCKRG | |||||||||||||||||||||||||||||||

| 7 | 19 | 24 | 69 | 40 | 50 | 228 | 77 | – | – | 189 | – | – | 22 | 114 | 42 | 110 | – | 2 | 60 | 70 | M12 | 27 | 35 | M6 | M8 | 21 | – | BT 10 | 160 – 60 | on request | 8.3 | – | – | 0.92 | – | – |

| 28 | 60 | 40 | M10 | |||||||||||||||||||||||||||||||||

| 8 | 24 | 50 | 256 | 91 | 194 | 18 | 36 | M8 | 8.7 | 1.5 | ||||||||||||||||||||||||||

| 28 | 60 | 41 | M10 | |||||||||||||||||||||||||||||||||

| 9 | 28 | 38 | 111 | 60 | 80 | 295 | 96 | 246 | 31 | 128 | 55 | 132 | 80 | 85 | M20 | 43 | 54 | M10 | M12 | 27 | BT 20 | 160 – 60 200 – 75 | 16 | 1.95 | ||||||||||||

| 42●●● | 48●● |

80 | 110 | 79 | M16 | |||||||||||||||||||||||||||||||

| 11 | 28 | 38 | 60 | 80 | 325 | 107 | 68.5 | 255 | 301 | 27 | 195 | 42 | 56 | M10 | M12 | 18 | 20.5 | 2.75 | 3.35 | |||||||||||||||||

| 42●●● | 48●● |

80 | 110 | 83 | M16 | |||||||||||||||||||||||||||||||

| 12 | 28 | 38 | 60 | 80 | 372 | 122 | 75 | 322 | 24 | 145 | 224 | 42 | 56 | M10 | M12 | 21.5 | 24.5 | 4.1 | 4.8 | |||||||||||||||||

| 42●●● | 48●● |

80 | 110 | 83 | M16 | |||||||||||||||||||||||||||||||

| 13 | 42 | 48 | 143 | 110 | 398 | 137 | 285 | 345 | 28 | 177 | 70 | 170 | 100 | M27 | 84 | M16 | 34 | 5 | BT 30 | 200 – 75 250 – 95 | 400 – 30 450 – 30 | 34 | 37 | 5.2 | 5.8 | |||||||||||

| 55●●● | 60●●● |

110 | 58.5 | 3 | 74 | 104 | M20 | |||||||||||||||||||||||||||||

| 15 | 48 | 55 | 145 | 110 | 460 | 151 | 87 | 137 | 343 | 411 | 461 | 35 | 206 | 80 | 259 | 110 | 120 | 80 | 70 | M16 | M20 | 35 | BT40 | 250 – 95 315 – 118 | 400 – 30 450 – 30 | 50.3 | 54.3 | 62 | 7.65 | 8.6 | 9.3 | |||||

| 60 | 65●●● | 140 | 100 | M20 | ||||||||||||||||||||||||||||||||

| 17 | 48 | 55 | 145 | 110 | 520 | 170 | 96 | 176 | 362 | 442 | 522 | 37 | 225 | 90 | 250 | 337 | 110 | 135 | 80 | M16 | M20 | 34 | 15 | BT 50 | 315 – 118 400 – 150 | 445 – 30 450 – 30 | 77 | 83 | 92 | 11.7 | 13.6 | 14.9 | ||||

| 60 | 65●●● |

140 | 103 | M20 | ||||||||||||||||||||||||||||||||

| 75● | 80● | – | 140 | 170 | 103 | 133 | ||||||||||||||||||||||||||||||

| 19 | 48 | 55 | 145 | 110 | 565 | 190 | 17 | 80 | M16 | M20 | 83 | 90 | 99 | 14.2 | 16.5 | 18.5 | ||||||||||||||||||||

| 60 | 65●●● |

140 | 103 | M20 | ||||||||||||||||||||||||||||||||

| 75● | 80● | – | 140 | 170 | 103 | 133 | ||||||||||||||||||||||||||||||

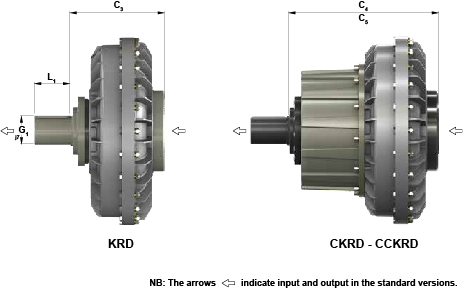

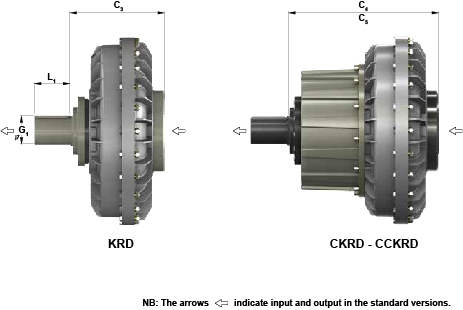

SERIES 7: KRD / CKRD – CCKRD

| C3 KRD | C4 CKRD | C5 CCKRD | G1 | L1 | Weight kg (without oil) | |||

|---|---|---|---|---|---|---|---|---|

| KRD | CKRD | CCKRD | ||||||

| 7 | 138 | – | – | 28 | 40 | 5.7 | – | – |

| 8 | 138 | 6.1 | ||||||

| 9 | 176 | 38 | 50 | 11.6 | ||||

| 11 | 185 | 231 | 42 | 13 | 15.5 | |||

| 12 | 252 | 16.7 | 19.7 | |||||

| 13 | 212 | 272 | 48 | 60 | 26.3 | 29.3 | ||

| 15 | 230 | 298 | 348 | 60 | 80 | 40.4 | 44.4 | 52.1 |

| 17 | 236 | 343 | 423 | 75 | 100 | 58.1 | 64.1 | 73.1 |

| 19 | 65.1 | 71.1 | 80.1 | |||||

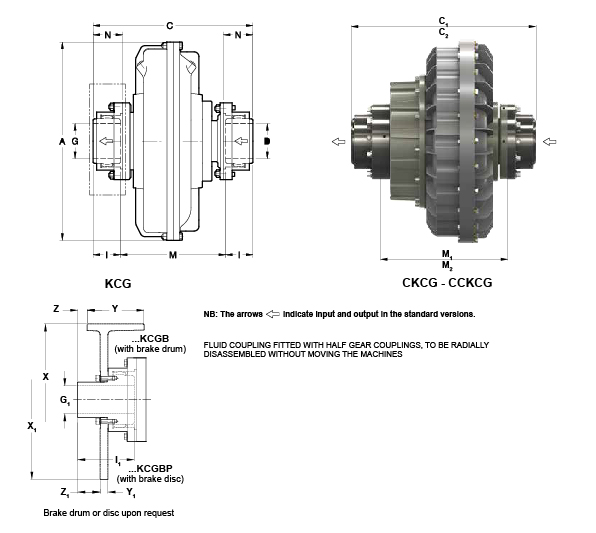

SERIES 7: KCG – KCGB / CKCGBP – CCKCGB – CCKCG

| A | C KCG | C1 CKCG | C2 CCKCG | D G max | G1 max | I | I1 | M KCG | M1 CKCG | M2 CCKCG | N | Brake drum X – Y | Z | Brake disc X1 – Y1 | Z1 | Gear Couplig Size | Weight kg (without oil) | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| KCG | CKGC | CCKCG | ||||||||||||||||||

| 7 | 228 | 229 | – | – | 50 | – | 43 | 80 | 143 | – | – | 44.5 | ● | ● | ● | ● | 1” E.I. (5) (6) | 11.3 | – | – |

| 8 | 256 | 234 | 148 | 11.7 | ||||||||||||||||

| 9 | 295 | 290.6 | 65 | 45 | 50 | 114 | 190.6 | 50.8 | 250-95 | 45 | 400-30 | 32 | 1” ½ E.I. (5) (6) | 22.9 | ||||||

| 11 | 325 | 299.6 | 345.6 | 199.6 | 245.6 | 24.9 | 27.4 | |||||||||||||

| 12 | 372 | 299.6 | 366.6 | 266.6 | 28.5 | 31.4 | ||||||||||||||

| 13 | 398 | 325.1 | 385.6 | 225.1 | 285.1 | 37.6 | 40.6 | |||||||||||||

| 15 | 460 | 410 | 478 | 528 | 95 | 65 | 76 | 146 | 258 | 326 | 376 | 79.5 | 250-95 315-118 | 57.5 21.5 | 400-30 445-30 | 44.5 | 2” ½ E.I. (5) (6) | 76.6 | 80.6 | 88.3 |

| 17 | 520 | 434 | 514 | 594 | 282 | 362 | 442 | 91.1 | 97.1 | 106.1 | ||||||||||

| 19 | 565 | 98.1 | 104.1 | 113.1 | ||||||||||||||||

| 21 | 620 | 503 | 603 | 693 | 111 | 90 | 90 | 165 | 323 | 423 | 513 | 93.5 | 315-118 | 26 | 560-30 | 38 | 3” E.I. (5) (6) | 142.3 | 152.3 | 160.3 |

| 24 | 714 | 400-150 | 15 | 710-30 | 38 | 160.3 | 170.3 | 178.3 | ||||||||||||

| 27 | 780 | 627 | 754 | 845 | 134 | 110 | 105 | 170 | 417 | 535 | 635 | 109.5 | 500-190 | 6 | 795-30 | 30 | 3” ½ E.I. (5) (6) | 253.2 | 272.2 | 291.2 |

| 29 | 860 | 656 | 774 | 874 | 446 | 564 | 664 | 307.2 | 325.2 | 335.2 | ||||||||||

| 34 | 1000 | 750 | 881 | 981 | 160 | 120 | 120 | 190 | 510 | 641 | 741 | 123.5 | ● | ● | 800-30 | 42 | 4” E.I. (5) (6) | 492.4 | 507.4 | 517.4 |

| 46 | 1330 | – | – | 1313.4 | 244 | 175 | 190 | 280 | – | – | 933.4 | 192.5 | ● | ● | ● | ● | 6” E.I. (5) (6) | – | – | 1333 |

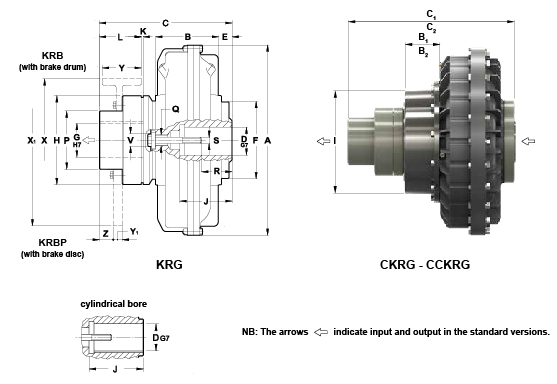

SERIES 21: KRG – KRB (w/Brake Drum) – KRBP (w/Brake Disc) / CKRG – CCKRG

| D | J | A | B KR… | B1 CKR… | B2 CCKR… | C KR… | C1 CKR… | C2 CCKR… | E | F | G | H | I | K | L | P | Q | R | S | V | Z | Flex coupling | Brake drum X – Y | Brake disc X1 – Y1 | Weight kg (without oil) KRG CKRG CCKRG | Oil max l KRG CKRG CCKRG | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 21 | ●80 | >90 | >170 | >620 | >205 | >110 | >199 | >433 | >533 | >623 | >45 | >250 | >110 | >290 | >400 | >3 | >140 | >170 | >M36 | >130 | >M20 | >M24 | >40 | >45 | >BT60 | >400 – 150 >500 – 190 | >560 – 30 >630 – 30 >710 – 30 >795 – 30 | >129 | >139 | >147 | >19 | >23 | >31 |

| ●●100 | >210 | >468 | >568 | >658 | >80 | >165 | >M24 | ||||||||||||||||||||||||||

| 24 | ●80 | >90 | >170 | >714 | >229 | >433 | >533 | >623 | >21 | >130 | >M20 | >M24 | >147 | >157 | >165 | >40 | >31.2 | >39 | |||||||||||||||

| ●●100 | >210 | >468 | >568 | >658 | >56 | >165 | >M24 | ||||||||||||||||||||||||||

| 27 | >120 max | >210 >max | >780 | >278 | >131 | >231 | >484 | >602 | >702 | >15 | >315 | >130 | >354 | >537 | >4 | >150 | >200 | >M45 | >167 | >M24 | >- | >20 | >BT80 | >500 – 190 | >710 – 30 >795 – 30 | >228 | >246 | >265 | >42 | >50 | >61 | ||

| >(for max bore) | |||||||||||||||||||||||||||||||||

| 29 | >135 max | >240 >max | >860 | >295 | >513 | >631 | >731 | >18 | >350 | >167 | >M24 | >- | >281 | >299 | >309 | >55 | >63 | >73 | |||||||||||||||

| >(for max bore) | |||||||||||||||||||||||||||||||||

| 34 | >150 max | >265 >max |

1000 |

>368 | >638 | >749 | >849 | >19 | >400 | >140 | >395 | >5 | >170 | >220 | >200 | >M36 | >- | >18 | >BT90 | >630 – 236 | >1000 – 30 | >472 | >482 | >496 | >82.5 | >92.5 | >101 | ||||||

| >(for max bore) | |||||||||||||||||||||||||||||||||

SERIES 21: KRD / CKRD – CCKRD

| C3 KRD | C4 CKRD | C5 CCKRD | G1 | L1 | Weight kg (without oil) | |||

|---|---|---|---|---|---|---|---|---|

| KRD | CKRD | CCKRD | ||||||

| 21 | 292 | 392 | 482 | 90 | 120 | 99.5 | 109.5 | 117.5 |

| 327* | 427* | 517* | ||||||

| 24 | 292 | 392 | 482 | 117.5 | 127.5 | 135.5 | ||

| 327* | 427* | 517* | ||||||

| 27 | 333 | 451 | 551 | 100 | 140 | 178 | 186 | 215 |

| 29 | 362 | 480 | 580 | 231 | 249 | 259 | ||

| 34 | 437 | 568 | 668 | 140 | 150 | 358 | 373 | 383 |

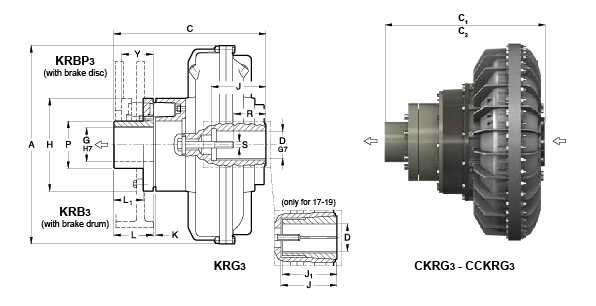

SERIES 17: KRG3 – KRB3 (w/Brake Drum) – KRBP3 (w/Brake Disc) / CKRG3 – CCKRG3

motor; only with the …KRB3 (with brake drum) coupling the electric motor must be moved by the value of ‘Y’.

‘Y’ = axial displacement male part of the coupling B3T necessary for the removal of the elastic elements.

| D | J | J1 | A | C | C1 | C2 | G | H | K | L | L1 | P | R | S | Y | Elastic coupling | Weight kg (without oil) | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| KRG3 | CKRG3 | CCKRG3 | ||||||||||||||||||||

| 17 | 48 | 55 | 145 | 110 | 520 | 418 | 498 | 578 | 90 | 240 | 3 | 110 | 82 | 130 | 80 | M16 | M20 | 82 | B3T-50 | 84 | 90 | 99 |

| 60 | >65●●● | 140 | 103 | M20 | ||||||||||||||||||

| 75● | 80● | – | 140 – 170 | 103 | 132 | |||||||||||||||||

| 19 | 48 | 55 | 145 | 110 | 565 | 80 | M16 | M20 | 91 | 97 | 106 | |||||||||||

| 60 | >65●●● | 140 | 103 | M20 | ||||||||||||||||||

| 75● | 80● | – | 140 – 170 | 103 | 132 | |||||||||||||||||

| 21 | 80● | 90 | 170 | – | 620 | 457 | 557 | 647 | 110 | 290 | 3 | 140 | 78 | 150 | 130 | M20 | M24 | 82 | B3T-60 | 134 | 144 | 152 |

| 100●● | 210 | 492 | 592 | 682 | 165 | M24 | ||||||||||||||||

| 24 | 80● | 90 | 170 | 714 | 457 | 557 | 647 | 130 | M20 | M24 | 152 | 162 | 170 | |||||||||

| 100●● | 210 | 492 | 592 | 682 | 165 | M24 | ||||||||||||||||

| 27 | 120 max | 210 | 780 | 566 | 684 | 784 | 130 | 354 | 4 | 150 | 112 | 180 | 167 | M24 | 120 | B3T-80 | 247 | 265 | 284 | |||

| 29 | 135 max | 240 | 860 | 595 | 713 | 813 | for max hole | 300 | 318 | 328 | ||||||||||||

| 34 | 150 max | 265 | 1000 | 704 | 815 | 915 | 150 | 395 | 5 | 170 | 119 | 205 | 200 | M36 | 151 | B3T-90 | 505 | 481 | 491 | |||

| for max hole | ||||||||||||||||||||||

| 46 | 180 max | 320 | – | 1330 | – | – | 1092 | 180 | 490 | 7 | 195 | 138 | 270 | 190 | M36 | 122 | B3T-100 | – | – | 1102 | ||

| for max hole | ||||||||||||||||||||||

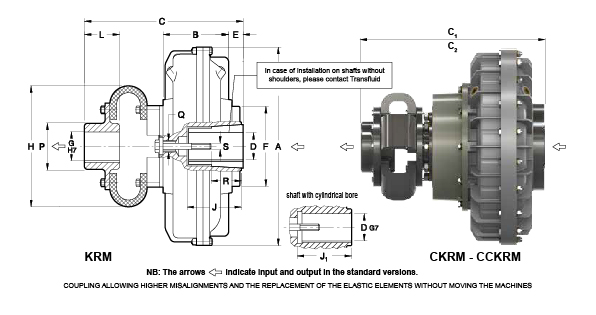

SERIES 9: KRM / CKRM – CCKRM

Taper Bush Version

| D | J | J1 | A | B | C KRM | C1 CKRM | C2 CCKRM | E | F | G | H | L | P | Q | R | S | Elastic coupling | Weight kg (without oil) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| KRM | CKRM | CCKRM | |||||||||||||||||||||||

| 9 | 28 | 38 | 111 | 60 | 80 | 295 | 96 | 276 | – | – | 31 | 128 | 50 | 185 | 50 | 80 | M20 | 43 | 54 | M10 | M12 | 53 F | 14.5 | – | – |

| 42●●● | – | 80 | – | 79 | M16 | ||||||||||||||||||||

| 11 | 28 | 38 | 60 | 80 | 325 | 107 | 285 | 331 | 27 | 42 | 56 | M10 | M12 | 16.5 | 19 | ||||||||||

| 42●●● | 48●● | 80 | 110 | 83 | M16 | ||||||||||||||||||||

| 12 | 38 | 80 | 372 | 122 | 352 | 24 | 145 | 42 | 56 | M12 | 20 | 23 | |||||||||||||

| 42●●● | 48●● | 80 | 110 | 83 | M16 | ||||||||||||||||||||

| 13 | 42 | 48 | 143 | 110 | 398 | 137 | 332 | 392 | 28 | 177 | 75 | 228 | 72 | 105 | M27 | 84 | 55 F | 33 | 36 | ||||||

| 55●●● | 60●●● | 110 | 58.5 | 74 | 104 | M20 | |||||||||||||||||||

| 15 | 48 | 55 | 145 | 110 | 460 | 151 | 367 | 435 | 485 | 35 | 206 | 80 | 235 | 80 | 112 | 80 | 70 | M16 | M20 | 56 F | 48 | 52 | 59.7 | ||

| 60 | 65●●● | 140 | 100 | M20 | |||||||||||||||||||||

| 17 | 48 | 55 | 145 | 110 | 520 | 170 | 380 | 460 | 540 | 37 | 225 | 75 | 288 | 90 | 120 | 80 | M16 | M20 | 58 F | 67 | 73 | 82 | |||

| 60 | 65●●● | 140 | 103 | M20 | |||||||||||||||||||||

| 75● | 80● | – | 140 | 170 | 105 | 135 | |||||||||||||||||||

| 19 | 48 | 55 | 145 | 110 | 565 | 190 | 17 | 80 | M16 | M20 | 74 | 80 | 89 | ||||||||||||

| 60 | 65●●● | 140 | 103 | M20 | |||||||||||||||||||||

| 75● | 80● | – | 140 | 170 | 105 | 135 | M20 | ||||||||||||||||||

Cylindrical Bore Version

| D | J | J1 | A | B | C KRM | C1 CKRM | C2 CCKRM | E | F | G | H | L | P | Q | R | S | Elastic coupling | Weight kg (without oil) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| KRM | CKRM | CCKRM | |||||||||||||||||||||||

| 9 | 28 | 38 | 111 | 60 | 80 | 295 | 96 | 276 | – | – | 31 | 128 | 50 | 185 | 50 | 80 | M20 | 43 | 54 | M10 | M12 | 53 F | 14.5 | – | – |

| 42●●● | – | 80 | – | 79 | M16 | ||||||||||||||||||||

| 11 | 28 | 38 | 60 | 80 | 325 | 107 | 285 | 331 | 27 | 42 | 56 | M10 | M12 | 16.5 | 19 | ||||||||||

| 42●●● | 48●● | 80 | 110 | 83 | M16 | ||||||||||||||||||||

| 12 | 38 | 80 | 372 | 122 | 352 | 24 | 145 | 42 | 56 | M12 | 20 | 23 | |||||||||||||

| 42●●● | 48●● | 80 | 110 | 83 | M16 | ||||||||||||||||||||

| 13 | 42 | 48 | 143 | 110 | 398 | 137 | 332 | 392 | 28 | 177 | 75 | 228 | 72 | 105 | M27 | 84 | 55 F | 33 | 36 | ||||||

| 55●●● | 60●●● | 110 | 58.5 | 74 | 104 | M20 | |||||||||||||||||||

| 15 | 48 | 55 | 145 | 110 | 460 | 151 | 367 | 435 | 485 | 35 | 206 | 80 | 235 | 80 | 112 | 80 | 70 | M16 | M20 | 56 F | 48 | 52 | 59.7 | ||

| 60 | 65●●● | 140 | 100 | M20 | |||||||||||||||||||||

| 17 | 48 | 55 | 145 | 110 | 520 | 170 | 380 | 460 | 540 | 37 | 225 | 75 | 288 | 90 | 120 | 80 | M16 | M20 | 58 F | 67 | 73 | 82 | |||

| 60 | 65●●● | 140 | 103 | M20 | |||||||||||||||||||||

| 75● | 80● | – | 140 | 170 | 105 | 135 | |||||||||||||||||||

| 19 | 48 | 55 | 145 | 110 | 565 | 190 | 17 | 80 | M16 | M20 | 74 | 80 | 89 | ||||||||||||

| 60 | 65●●● | 140 | 103 | M20 | |||||||||||||||||||||

| 75● | 80● | – | 140 | 170 | 105 | 135 | M20 | ||||||||||||||||||

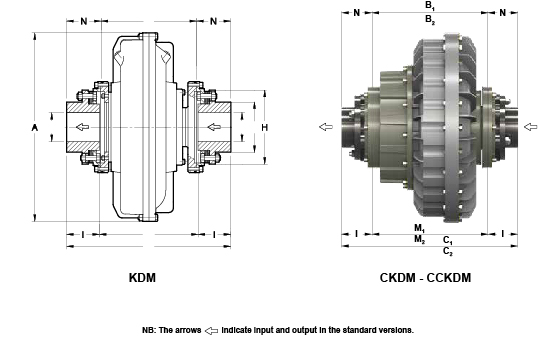

Series 11: KDM / CKDM – CCKDM

| A | B KDM | B1 CKDM | B2 CCKDM | C KDM | C1 CKDM | C2 CCKDM | D G min | D G max | H | I | M KDM | M1 CKDM | M2 CCKDM | N | P | Disc coupling size | Weight kg (without oil) | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| KDM | CKDM | CCKDM | ||||||||||||||||||

| 11 | 325 | 186 | 232 | – | 289 | 335 | – | 16 | 55 | 123 | 50 | 189 | 235 | – | 51.5 | 76 | 1055 | 22.5 | 25 | – |

| 12 | 372 | 253 | 356 | 256 | 26 | 29 | ||||||||||||||

| 13 | 398 | 216 | 276 | 339 | 399 | 21 | 65 | 147 | 60 | 219 | 279 | 61.5 | 88 | 1065 | 41.3 | 44.3 | ||||

| 15 | 460 | 246 | 314 | 364 | 391 | 459 | 509 | 21 | 75 | 166 | 70 | 251 | 319 | 369 | 72.5 | 104 | 1075 | 65 | 69 | 76.7 |

| 17 | 520 | 269 | 349 | 429 | 444 | 524 | 604 | 31 | 90 | 192 | 85 | 274 | 354 | 434 | 87.5 | 122 | 1085 | 89 | 95 | 104 |

| 19 | 565 | 96 | 102 | 111 | ||||||||||||||||

| 21 | 620 | 315 | 415 | 505 | 540 | 640 | 730 | 41 | 115 | 244 | 110 | 320 | 420 | 510 | 112.5 | 154 | 1110 | 159 | 169 | 177 |

| 24 | 714 | 177 | 187 | 195 | ||||||||||||||||

| 27 | 780 | 358 | 476 | 576 | 644 | 762 | 862 | 51 | 135 | 303 | 140 | 364 | 482 | 582 | 143 | 196 | 1140 | 289 | 307 | 326 |

| 29 | 860 | 387 | 505 | 605 | 673 | 791 | 891 | 393 | 511 | 611 | 342 | 360 | 370 | |||||||

| 34 | 1000 | 442 | 573 | 673 | 768 | 899 | 999 | 61 | 165 | 340 | 160 | 448 | 579 | 679 | 163 | 228 | 1160 | 556 | 562 | 572 |

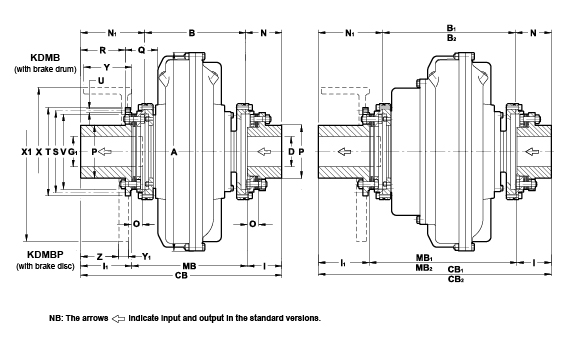

SERIES 12: KDMB (w/Brake Drum) – KDMBP (w/Brake Disc) / CKDMB – CCKDMB

| A | B KDM | B1 CKDM | B2 CCKDM | CB KD… | CB1 CKD… | CB2 CCKDM… | D max | G1 max | I | I1 | MB KD…. | MB1 CKD… | MB2 CCKDM… | N | N1 St | O | P | Q | R | S ÷0.1 | T f7 | U | V | Z | Disc coupling size | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 12 | 372 | 186 | 253 | – | 336.5 | 403.5 | – | 55 | 60 | 50 | 80 | 206.5 | 273.5 | – | 51.5 | 99 | 17.5 | 76 | 67 | 69 | 128 | 142 | 8 | M8 | 114 | – | 1055 | |

| 13 | 398 | 216 | 276 | 440.5 | 500.5 | 65 | 65 | 60 | 140 | 170 | 240.5 | 300.5 | 61.5 | 163 | 21.5 | 88 | 78 | 129 | 155 | 170 | 12 | 140 | 1065 | |||||

| 15 | 460 | 246 | 314 | 364 | 495.5 | 563.5 | 613.5 | 75 | 80 | 70 | 150 | 275.5 | 343.5 | 393.5 | 72.5 | 177 | 24.5 | 104 | 98 | 134 | 175 | 192 | M10 | 157 | 109 | 1075 | ||

| 17 | 520 | 269 | 349 | 429 | 548.5 | 628.5 | 708.5 | 90 | 95 | 85 | 160 | 210 | 303.5 | 383.5 | 463.5 | 87.5 | 192 | 29.5 | 122 | 107 | 143 | 204 | 224 | 185 | 118 | 1085 | ||

| 19 | 565 | 87 | ||||||||||||||||||||||||||

| 21 | 620 | 315 | 415 | 505 | 628.5 | 728.5 | 818.5 | 115 | 120 | 110 | 240 | 358.5 | 458.5 | 548.5 | 112.5 | 201 | 38.5 | 154 | 133 | 137 | 256 | 276 | M12 | 234 | 112 | 1110 | ||

| 24 | 714 | 109 | ||||||||||||||||||||||||||

| 27 | 780 | 358 | 476 | 576 | 731.5 | 849.5 | 949.5 | 135 | 145 | 140 | 180 | 411.5 | 529.5 | 629.5 | 143 | 230.5 | 47.5 | 196 | 107 | 155 | 315 | 338 | M14 | 286 | 133 | 1140 | ||

| 29 | 860 | 387 | 505 | 605 | 760.5 | 878.5 | 978.5 | 440.5 | 558.5 | 658.5 | 109 | |||||||||||||||||

| 34 | 1000 | 442 | 573 | 673 | 845.5 | 976.5 | 1076.5 | 165 | 175 | 160 | 505.5 | 636.5 | 736.5 | 163 | 240.5 | 57.5 | 228 | 124 | 152 | 356 | 382 | M16 | 325 | 130 | 1160 | |||

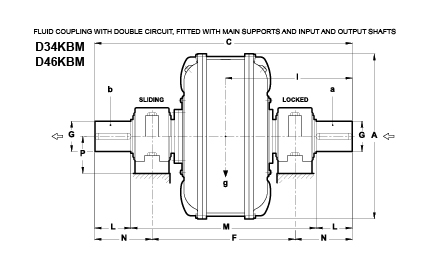

SERIES D34KBM – D46KBM

| SERIES | A | C | F | D-G m6 | L | M | N | P |

|---|---|---|---|---|---|---|---|---|

| D34KBM | 1000 | 1400 | 855 | 140 | 140 | 1120 | 257.5 | 170 |

| D46KBM | 1330 | 1900 | 1275 | 160 | 200 | 1550 | 312.5 | 170 |

| WEIGHT Kg (Without oil) | OIL max. l | CENTER OF GRAVITY g l | MOMENT OF INERTIA J (WR2) Kgm² | ||

|---|---|---|---|---|---|

| Kg | mm | a | b | ||

| 810 | 162 | 952 | 710 | 26.19 | 64.25 |

| 2200 | 390 | 2514 | 955 | 91.25 | 183.7 |

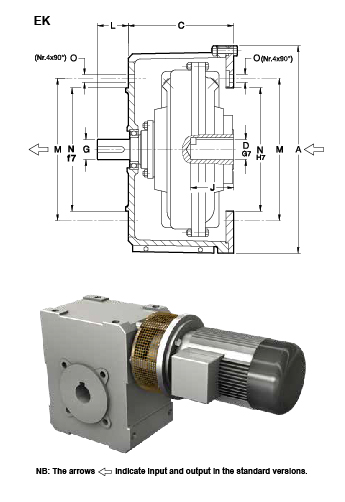

EK

| D | J | G | L | A | C | M | N | O | Weight kg (without oil) | OIL max l | Electric motors | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| TYPE | kW 1500 rpm | ||||||||||||

| 7 | ● 24 | 52 | 24 | 38 | 269 | 132 | 165 | 130 | 11 | 11.4 | 0.92 | 90S – 90L **90LL | 1.1 -1.5 1.6 |

| 8 | ● 28 | 62 | 28 h7 | 44 | 299 | 142 | 215 | 180 | 13 | 12.2 | 1.5 | 100 L 112 M | 2.2 -3 4 |

| 9 | ● 38 | 82 | 38 | 57 | 399 | 187 | 265 | 230 | 13 | 26.9 | 1.95 | 132S – 132M ** 132L | 5.5 – 7.5 9.2 |

| 11 | ● 42 | 112 | 42 | 63 | 399 | 187 | 300 | 250 | 17 | 28.3 | 2.75 | 160M -160 L | 11 – 15 |

| 12 | ●● 48 | 112 | 48 j7 | 65 | 485 | 214 | 300 | 250 | 17 | 66 | 4.1 | 180 M 180 L | 18.5 22 |

| 13 | ● 55 | 112 | 55 | 80 | 350 | 300 | 76 | 5.2 | 200 L | 30 | |||

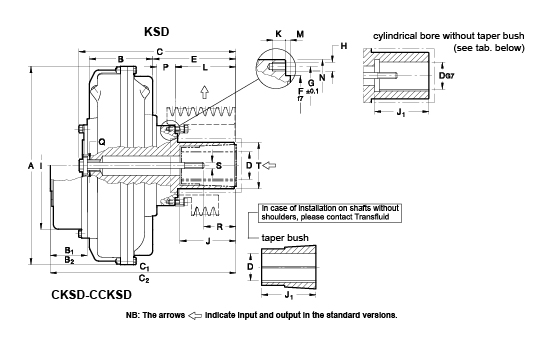

SERIES 7: – KSD – CKSD – CCKSD

Taper Bush Version

| D | J | J1 | A | B

KSD |

B1

CKSD |

B2

CCKSD |

C

max |

C1

CKSD |

C2

CCKSD |

E | F | G | H | I | K | L | M | N | P | Q | R | S | T

max |

||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 7 | 19 | 24 | 69 | 40 | 50 | 228 | 77 | – | – | 159 | – | – | 55 | 75 | 90 | 4 | M6 | – | 8 | 35 | 3 | 114 | 14 | M12 | 29 | 38 | M6 | M8 | 50 |

| 28 | 60 | 174 | 70 | 50 | 43 | M10 | |||||||||||||||||||||||

| 8 | 24 | 50 | 256 | 91 | 194 | 81 | 65 | 33 | M8 | ||||||||||||||||||||

| 28 | 60 | 43 | M10 | ||||||||||||||||||||||||||

| 9 | 28 | 38 | 111 | 60 | 80 | 295 | 96 | 250 | 116 | 96 | 114 | 8 | M8 | 13 | 85 | 5 | 128 | 20 | M20 | 39 | 61 | M10 | M12 | 69 | |||||

| ●●●42 | 80 | 78 | M16 | ||||||||||||||||||||||||||

| 11 | 28 | 38 | 60 | 80 | 325 | 107 | 73.5 | 259 | 289.5 | 113 | 195 | 38 | 59 | M10 | M12 | ||||||||||||||

| ●●●42 | 80 | 78 | M16 | ||||||||||||||||||||||||||

| 12 | 38 | 42 | 113 | 80 | 110 | 372 | 122 | 80 | 274 | 327 | 125 | 112 | 130 | 224 | 98 | 7 | 145 | 22 | 54 | 83 | M12 | M16 | 80 | ||||||

| ●●●48 | 110 | 83 | M16 | ||||||||||||||||||||||||||

| 13 | 42 | 48 | 144 | 110 | 398 | 137 | 367 | 407 | 190 | 135 | 155 | 12 | 158 | 6 | 177 | 29 | M27 | 76 | M16 | 88 | |||||||||

| ●●●55 | ●●●60 | 110 | 58.5 | 76 | 106 | M20 | |||||||||||||||||||||||

| 15 | 48 | 55 | 145 | 110 | 460 | 151 | 92 | 142 | 390 | 438 | 488 | 195 | 150 | 178 | M10 | 264 | 17 | 159 | 7 | 206 | 28 | 80 | 70 | M16 | M20 | 100 | |||

| 60 | ●●●65 | 140 | 100 | M20 | |||||||||||||||||||||||||

| 17 | 48 | 55 | 145 | 110 | 520 | 170 | 101 | 181 | 455 | 516 | 596 | 245 | 180 | 200 | 337 | 17 | 180 | 225 | 60 | 69 | M20 | 132 | |||||||

| 60 | ●●●65 | 140 | 99 | ||||||||||||||||||||||||||

| ●75 | ●80 | – | 140 | 170 | 99 | 139 | |||||||||||||||||||||||

| 19 | 48 | 55 | 145 | 110 | 565 | 190 | 225 | 45 | 69 | ||||||||||||||||||||

| 60 | ●●●65 | 140 | 99 | ||||||||||||||||||||||||||

| ●75 | ●80 | – | 140 | 170 | 99 | 139 | |||||||||||||||||||||||

Cylindrical Bore Version

| 21 | ●80 | – | 170 | 620 | 205 | 115 | 205 | 505 | 580 | 670 | 260 | 200 | 228 | 8 | M14 | 400 | 23 | 190 | 7 | 250 | 57 | M46 | 135 | M20 | 145 |

| ●100 | 210 | 545 | 620 | 710 | 300 | 230 | 165 | M24 | |||||||||||||||||

| 24 | ●80 | 170 | 714 | 229 | 505 | 580 | 670 | 236 | 190 | M46 | 135 | M20 | |||||||||||||

| ●100 | 210 | 545 | 620 | 710 | 276 | 230 | 165 | M24 | |||||||||||||||||

| 27 | 120 max | 210 | 780 | 278 | 138 | CONSULT OUR ENGINEERS | |||||||||||||||||||

Resources