TransDrive ANSI & BS Stainless Steel Roller Chain

Crafted from high-grade stainless steel, TransDrive Stainless Steel roller chains deliver outstanding strength, corrosion resistance, and longevity.

The TransDrive Stainless Steel (SS) roller chain is a high-quality, durable, and reliable power transmission solution designed for demanding industrial applications. Crafted from premium-grade stainless steel, this roller chain offers exceptional strength, corrosion resistance, and longevity. With its excellent performance characteristics, it ensures smooth and efficient power transmission in a wide range of environments.

Features and Benefits

- Premium Stainless Steel Construction: Manufactured using top-grade stainless steel materials, this roller chain provides superior strength, durability, and resistance to corrosion, wear, and impact.

- Reliable Power Transmission: The precisely engineered roller design ensures efficient power transfer, minimizing energy loss and maximizing the overall performance of your machinery or equipment.

- Environmentally Resistant: This stainless steel roller chain is specifically designed to withstand harsh and challenging operating conditions. It exhibits excellent resistance to environmental factors such as moisture, chemicals, high temperatures, and even extreme cold, making it suitable for a wide range of industrial environments.

- Low Maintenance: The stainless steel construction significantly reduces the need for frequent lubrication and maintenance, resulting in cost savings and increased productivity.

- Compatibility: This roller chain conforms to industry-standard dimensions, ensuring easy replacement and compatibility with existing equipment or machinery.

Applications

- Food processing and packaging

- Pharmaceutical manufacturing

- Chemical processing

- Wastewater treatment

- Bottling and packaging machinery

- High-temperature environments

- Corrosive environments

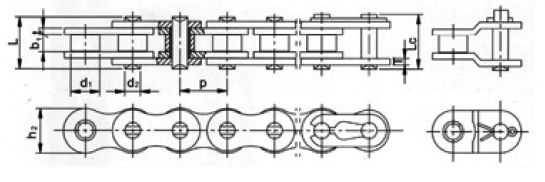

| Chain No. | Pitch | Roller Diameter | Width Between Inner Plates | Pin Diameter | Pin Length | Inner Plate Depth | Plate Thickness | Ultimate Tensile Strength | Average Tensile Strength | Weight per Meter | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| P | d1 max | b1 min | d2 max | L max | Lc max | h2 max | t/T | Q(ISO/DIN) min | Q0 | q = | |

| *35SS | 9.53 | 5.08 | 4.77 | 3.58 | 12.40 | 13.17 | 9.00 | 1.30 | 5.50 | 6.60 | 0.33 |

| 40SS | 12.70 | 7.95 | 7.85 | 3.96 | 16.60 | 17.80 | 12.20 | 1.50 | 9.70 | 11.60 | 0.63 |

| 50SS | 15.88 | 10.16 | 9.40 | 5.08 | 20.70 | 22.2 | 15.09 | 2.06 | 15.30 | 18.50 | 1.03 |

| 60SS | 19.05 | 11.91 | 12.57 | 5.94 | 25.9 | 27.70 | 18.00 | 2.44 | 21.80 | 26.40 | 1.51 |

| 80SS | 25.40 | 15.88 | 15.75 | 7.92 | 32.7 | 35.00 | 24.00 | 3.26 | 38.90 | 46.60 | 2.62 |

| 100SS | 31.75 | 19.05 | 18.90 | 9.53 | 40.40 | 44.70 | 30.00 | 4.00 | 59.00 | 70.20 | 3.94 |

| #06BSS | 9.53 | 6.35 | 5.72 | 3.28 | 13.15 | 14.10 | 8.20 | 1.30 | 6.20 | 7.30 | 0.41 |

| 08BSS | 12.70 | 8.51 | 7.75 | 4.45 | 16.70 | 18.20 | 11.80 | 1.60 | 12.00 | 14.30 | 0.70 |

| 10BSS | 15.88 | 10.16 | 9.65 | 5.08 | 19.50 | 20.90 | 14.70 | 1.70 | 14.50 | 17.20 | 0.94 |

| 12BSS | 19.05 | 12.07 | 11.68 | 5.72 | 22.50 | 24.20 | 16.00 | 1.85 | 18.50 | 22.00 | 1.16 |

| 16BSS | 25.40 | 15.88 | 17.02 | 8.28 | 36.10 | 37.40 | 21.00 | 4.15/3.10 | 40.00 | 47.60 | 2.13 |

| 20BSS | 31.75 | 19.05 | 19.56 | 10.19 | 41.30 | 45.00 | 26.40 | 4.50/3.50 | 59.00 | 69.60 | 3.73 |

Resources