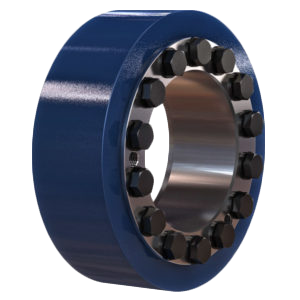

TAS Schäfer Torque Shrink Discs

2-Part shrink discs, focused purely on raw torque.

Benefits

- Compensation for an increased fit clearance

- Various designs and special finishes are available

- Transmittable torque from 36Nm to 3.356.000Nm

- Nominal diameter from 14mm to 660mm

- Easy assembly and disassembly

Torque shrink discs are external clamping elements consisting of a thrust ring and a sleeve. By tightening the clamping screws with a given screw-tightening torque, the thrust ring is pulled axially onto the sleeve. Using conical surfaces reduces the sleeve’s inner diameter, thus exerting a radial clamping force on the hollow shaft. The clamping force applied by the shrink disc connection creates a frictional connection between the shaft and hub at the contact surfaces. Torque shrink discs have a smaller cone angle compared to 3-piece shrink discs, this is in the self-locking. Due to the small cone angle, it is necessary for the sleeve to have additional impression threads. With the help of these impression threads, the thrust collar and sleeve can be easily pressed apart during disassembly. Torque shrink discs have a defined push-on displacement, which means that assembly can be carried out without a torque spanner. The clamping screws of the torque shrink discs are tightened evenly in a row until the face of the sleeve is flush with the face of the thrust collar. The torques specified in the catalogue can be transmitted as soon as this assembly condition is reached.

Torque shrink discs are available in 3 different versions. For the smallest torques and small installation spaces, the series TAS 3173 is suitable. For high to very high transmittable torques, you can choose between the TAS 3381 and the TAS 3393. Depending on the installation space available to you and the required torque, we will find the right solution for you together. Appropriate solutions can also be offered for special corrosion protection or low-temperature environments.

Torque shrink discs can transmit 20%-30% higher torques. In combination with the simplified handling, the torque shrink discs have proven themselves in practice, especially in the field of mining and conveyor technology. However, these shrink discs are used as standard in the entire area of frictionally engaged shaft-hub connections, e.g. in drive technology, the oil and gas industry, the timber industry or hollow shaft gearboxes.

Types of Torque Shrink Discs