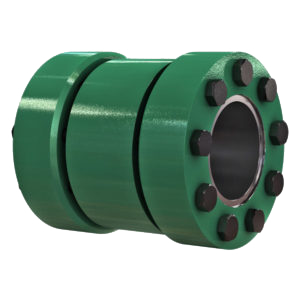

TAS Schäfer Shaft Couplings – W WLA, WLB & WK

For the safe and secure connection between shaft ends.

Benefits

- Compact design

- Rigid and backlash-free connection of shaft ends

- Transmittable torque from 80Nm to 1.513.000Nm

- Shaft diameter from 10mm to 420mm

- Individual special solutions possible

Rigid shaft couplings of the “W”, “WLA”, “WLB” and “WK” series are used for the safe and backlash-free connection of two shaft ends. They consist of a connecting sleeve and two thrust rings. Depending on the series, the shaft couplings are also equipped with a connecting sleeve and two shrink discs. The functional principle is identical for all series. The individual pressure rings or shrink discs generate radial pressure on the functional surfaces of the connecting sleeve, creating a frictional connection between the connecting sleeve and the shaft.

The frictional connection of the two shaft ends allows torques, bending moments as well as axial forces to be transmitted reliably. The advantage of shaft couplings of the “W”, “WLA”, “WLB” and “WK” series is their compact design. Compared to other shaft couplings, they are significantly smaller.

Compared to flexible shaft couplings, the drive or gear side of a rigid shaft coupling must be elastically supported. Due to its type of connection, the rigid shaft coupling is not able to compensate for shaft misalignment. This means that the shafts must be precisely aligned with each other before assembly. Any shocks, deformations or vibrations that occur are compensated for by the elastically mounted part of the drive train.

The shaft couplings of the “W”, “WLA”, “WLB” and “WK” series are used, for example, in the marine industry, materials handling, mixing and process engineering, as well as in the entire drive technology where a safe and backlash-free connection of two shaft ends is required.

Types of Shaft Couplings