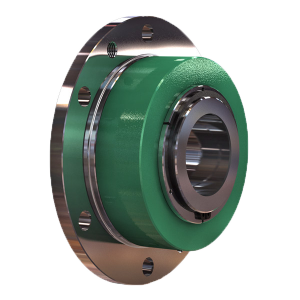

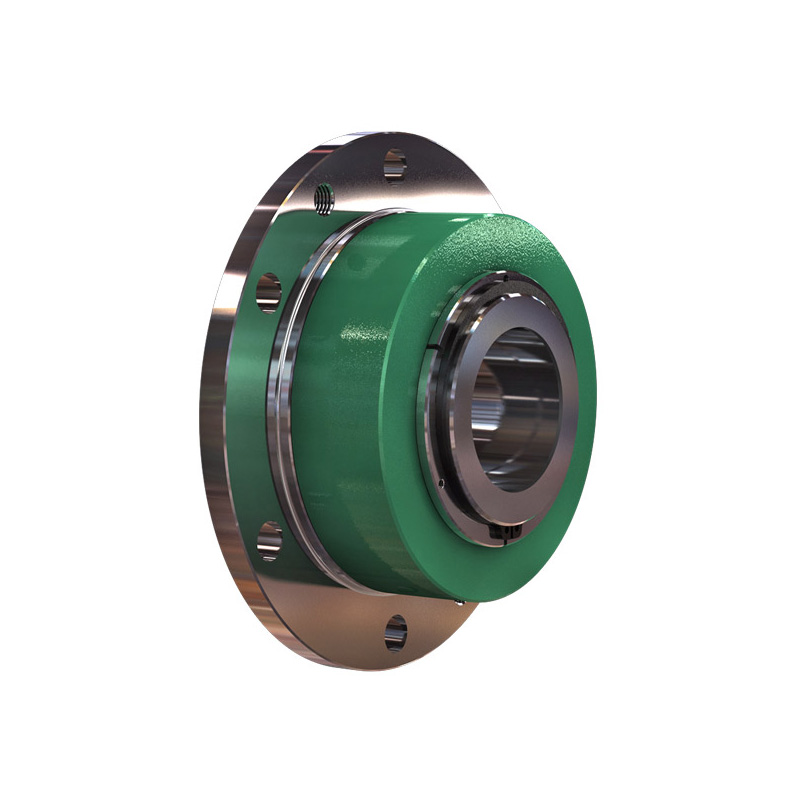

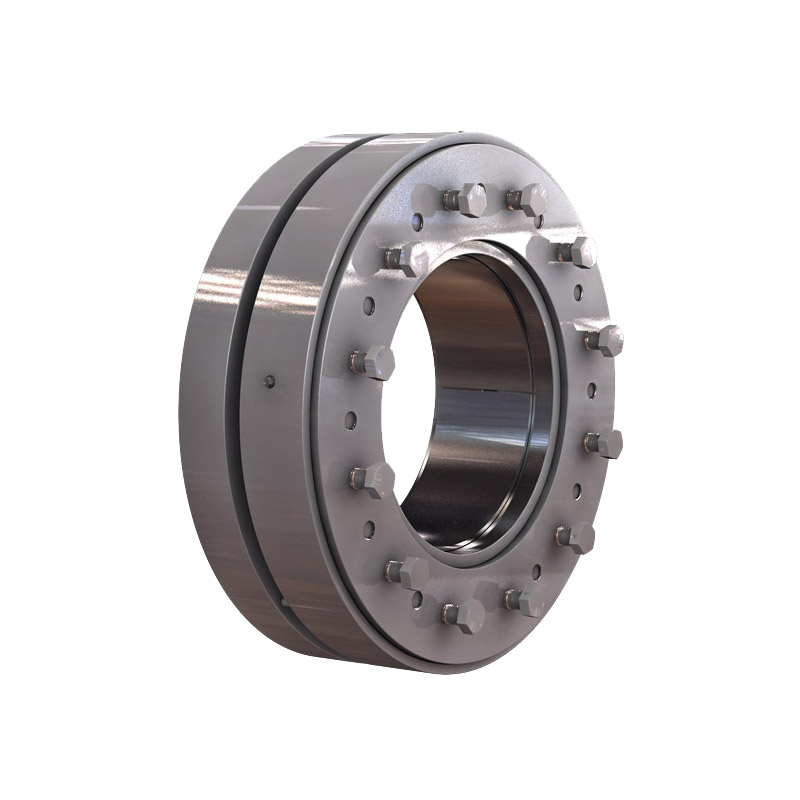

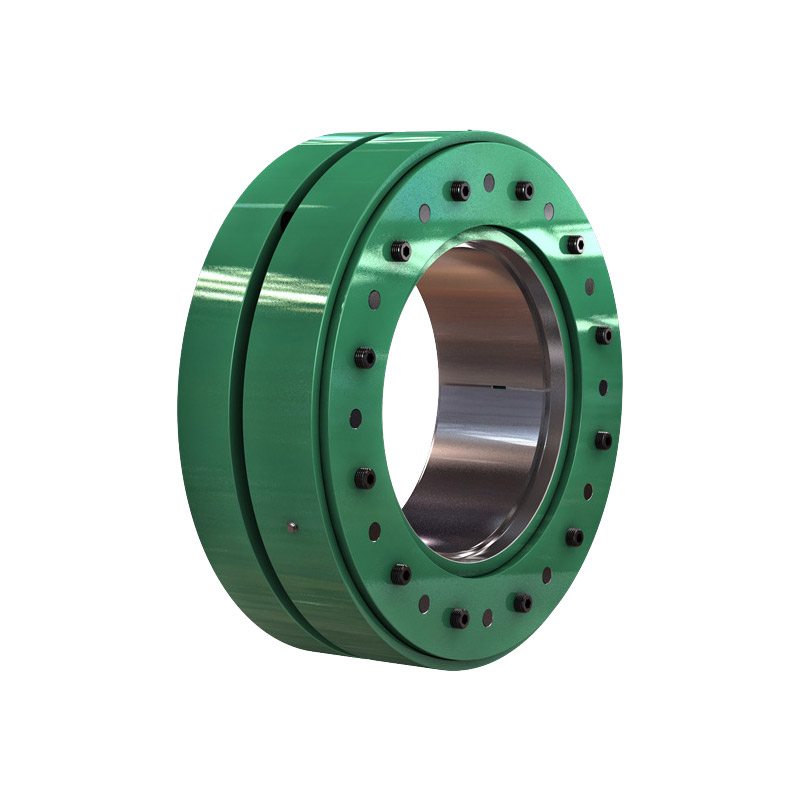

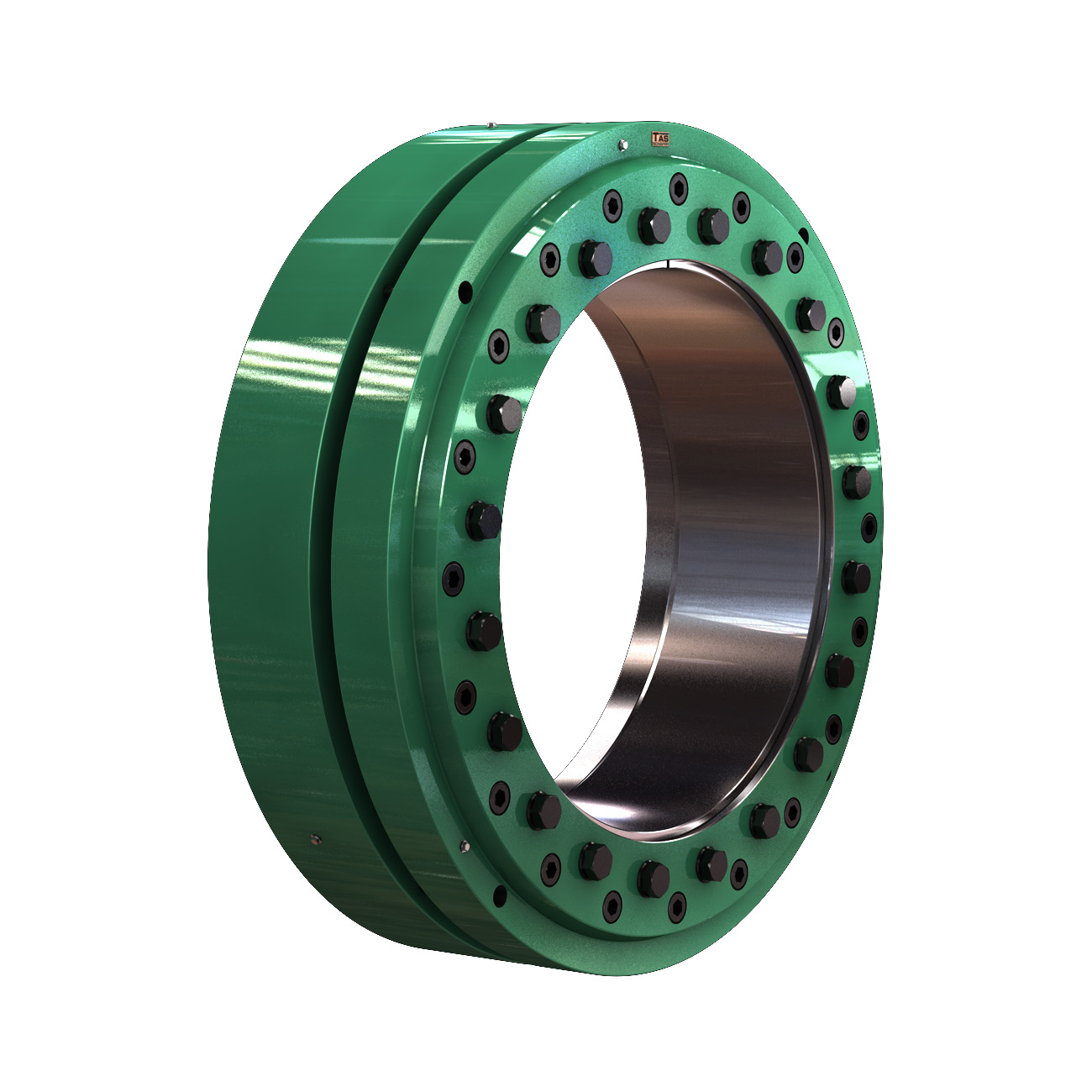

TAS Schäfer Hydraulic Shrink Discs – SHS

Fast, low-pressure shaft–hub connections with major time savings and high-torque reliability for industrial drive systems.

The TAS Schäfer SHS Series uses hydraulic tensioning instead of manual bolt tightening, allowing a secure shaft–hub connection in minutes. A 360 mm disc can be assembled in as little as 8 minutes, compared with up to 180 minutes for an equivalent mechanical version.

This dramatic reduction in labour means installations and changeouts can be completed quickly, even on large drives, cutting downtime and improving workflow efficiency.

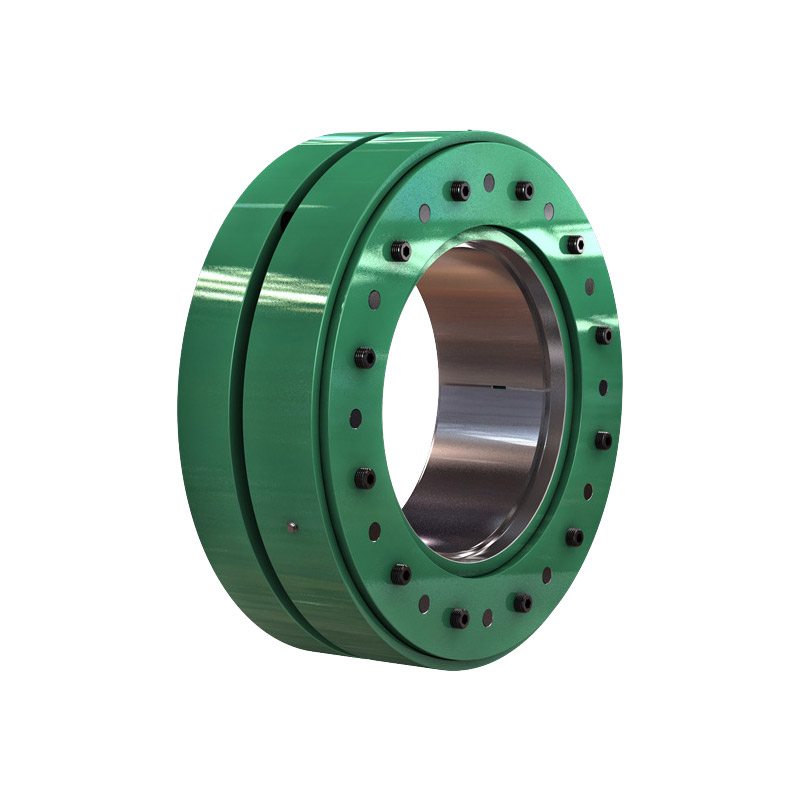

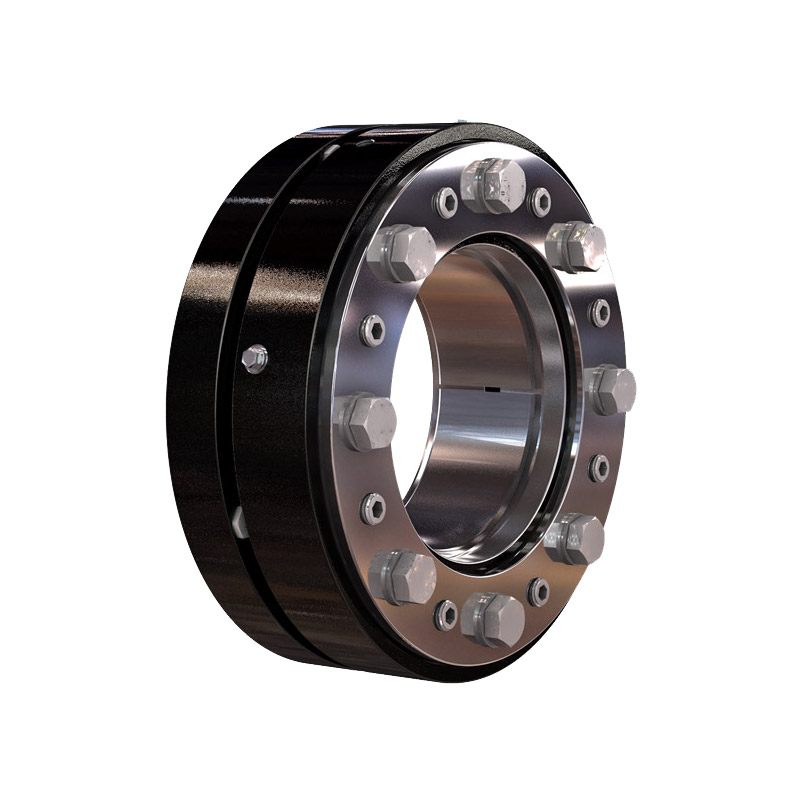

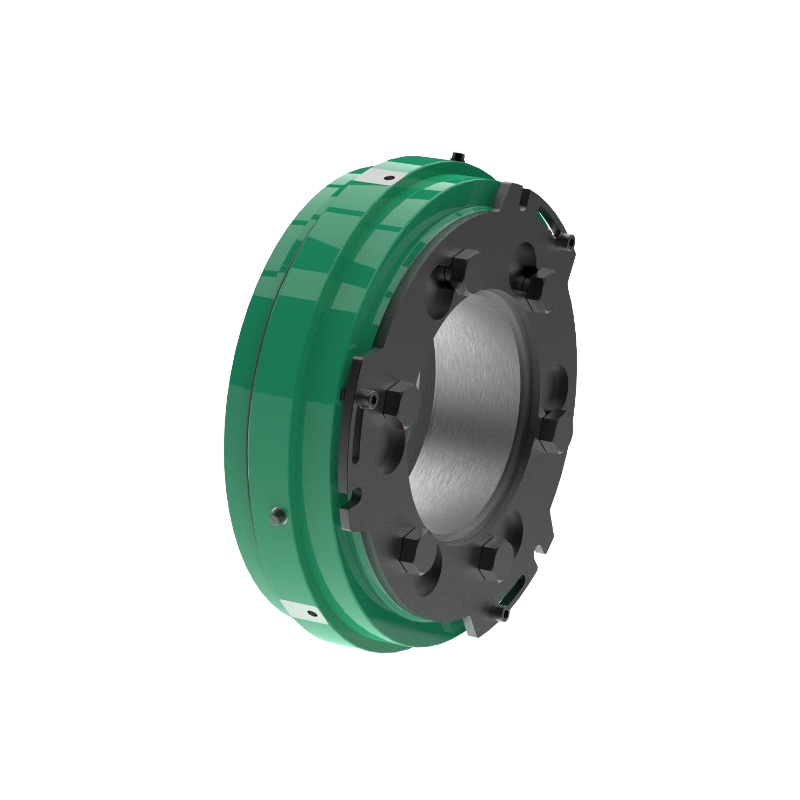

The SHS design uses a three-part shrink disc that keeps the friction surfaces separate from the hydraulic system. This avoids oil contamination, ensures consistent performance, and extends component life.

Why Choose SHS Hydraulic Shrink Discs

- Up to 95% faster installation than mechanical shrink discs

- Quick clamping at around 180 bar

- Inner ring adaptable to multiple shaft or hub sizes

- Customer-serviceable design with easy parts replacement

- High torque transmission with backlash-free performance

- Hybrid use: can be mechanically released or partially tensioned when hydraulics are unavailable

Designed for Reliability and Easy Maintenance

Once installed, SHS shrink discs offer stable, high-torque performance across demanding applications. After long operating periods, the disc can be dismantled simply by loosening the screws — no hydraulic pressure or specialised tools required. Seal changes and routine maintenance can be carried out in-house, reducing service costs and avoiding delays.

Typical Applications

Hydraulic shrink discs of the SHS type are widely used across industries where precision, safety, and repeatability are essential.

Common examples include:

- Drive technology and test benches

- Gearbox-to-shaft couplings

- Wind energy systems

- Hydraulic motor drives

- Conveyor and heavy-duty power transmission equipment

Featured Products

Resources

Videos

Related Products