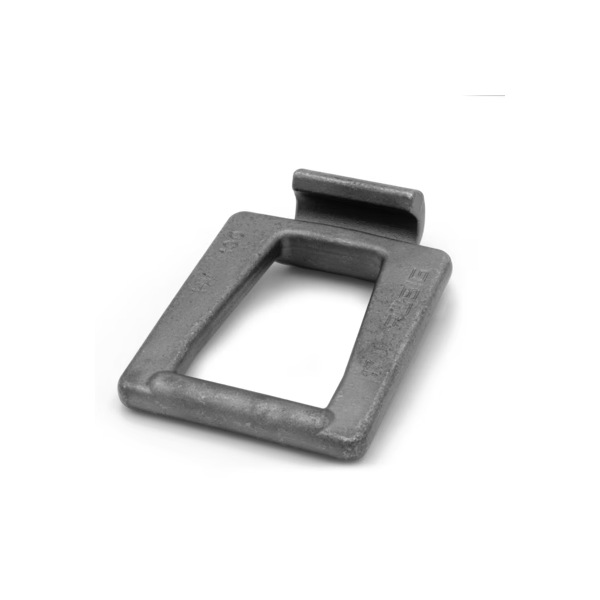

Rubig Chain Link – T Series

The “T” series chain delivers maximum strength and durability, built to withstand harsh conditions, resist wear, and be easily welded or disassembled by hand.

The “T” series chain is engineered for the most demanding operations. Its robust construction, combined with an optimised fibre composition and microstructure, ensures an exceptionally high breaking load. The chain is highly resistant to wear and weather conditions, providing reliable performance over time. Designed for convenience, it can be welded effortlessly and disassembled by hand, making maintenance and adaptation straightforward.

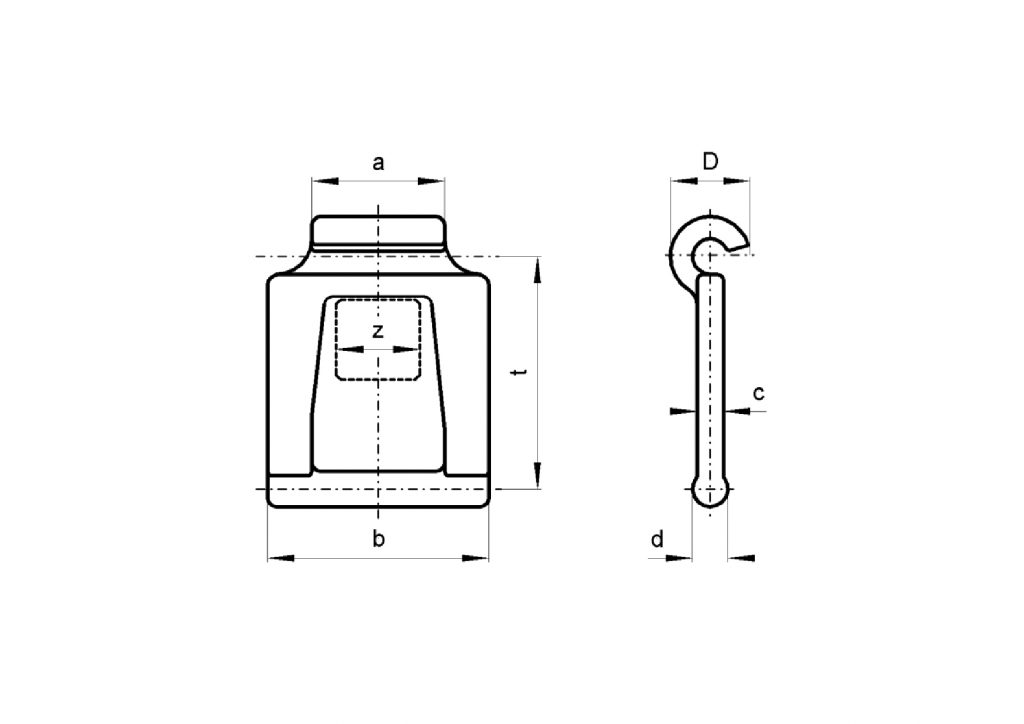

| Type | a (mm) | b (mm) | c (mm) | d (mm) | D (mm) | max (*) recommended working load | breaking strain |

|---|---|---|---|---|---|---|---|

| 29.3 HF | 17.5 | 30 | 4 | 6 | 15 | 8kN | 24kN |

| 35 HF | 19.5 | 32 | 4 | 6 | 15 | 8kN | 24kN |

| 35 HV | 19.5 | 32 | 4 | 6 | 15 | 9kN | 30kN |

| 39 HF | 20.5 | 36 | 5.5 | 7 | 16.5 | 11kN | 36kN |

| 39 HV | 20.5 | 36 | 5.5 | 7 | 16.5 | 13kN | 40kN |

| 41.3 HF | 20.5 | 36 | 5.5 | 7 | 16.5 | 11kN | 36kN |

| 44 HF | 23 | 43 | 5 | 8 | 18.5 | 13kN | 40kN |

| 49 HF | 20.5 | 36 | 5.5 | 7 | 16.5 | 11kN | 24kN |

| 49 HV | 20.5 | 36 | 5.5 | 7 | 16.5 | 13kN | 40kN |

| 49 INOX | 20.5 | 36 | 5.5 | 7 | 16.5 | 8kN | 36kN |

| 49 E | 20.5 | 36 | 5.5 | 7 | 16.5 | 13kN | 36kN |

| 57 HF | 20.5 | 36 | 5.5 | 7 | 16.5 | 11kN | 40kN |

| 59S HF | 20.5 | 36 | 5.5 | 7 | 16.5 | 11kN | 45kN |

| 59S HV | 20.5 | 36 | 5.5 | 7 | 16.5 | 13kN | 24kN |

| 59S INOX | 20.5 | 36 | 5.5 | 7 | 16.5 | 8kN | 60kN |

| 59 HF | 28 | 49 | 5 | 7.5 | 19 | 17kN | 75kN |

| 59 HV | 28 | 49 | 5 | 7.5 | 19 | 19kN | 75kN |

| 59 E | 28 | 49 | 5 | 7.5 | 19 | 20kN | 80kN |

| 67 HF | 37 | 62 | 7 | 10 | 25 | 29kN | 100kN |

| 67 HV | 37 | 62 | 7 | 10 | 25 | 33kN | 100kN |

| 67 E | 37 | 62 | 7 | 10 | 25 | 35kN | 100kN |

| 67 HVB | 37 | 67 | 7.5 | 10 | 25 | 33kN | 100kN |

| 67 EB | 37 | 67 | 7.5 | 10 | 25 | 33kN | 100kN |

| 78.5 HF | 47 | 82 | 8 | 13 | 32 | 48kN | 125kN |

| 78.5 HV | 47 | 82 | 8 | 13 | 32 | 55kN | 170kN |

| 78.5 E | 47 | 82 | 8 | 13 | 32 | 55kN | 170kN |

| 100 HV | 49 | 85 | 10 | 14 | 35 | 64kN | 230kN |

| 100 E | 49 | 85 | 10 | 14 | 35 | 64kN | 230kN |

| 125 HV | 50 | 85 | 11.5 | 16 | 40 | 80kN | 280kN |

Benefits

- Weather-resistant

- Low weight

- Weldable

- Easy to assemble and disassemble by hand

Applications

- Heavy-duty conveyors in mining and processing plants

- Screening and cleaning systems in hydroelectric power plants

- Shredder and recycling machinery

- Agricultural and forestry equipment under high stress

- Material transport in harsh or abrasive environments

- Industrial machinery requiring high-load handling

- Situations where frequent disassembly or maintenance is needed

Industries

- Mining and mineral processing

- Hydroelectric power and water treatment

- Recycling and waste management

- Forestry and agriculture

- Heavy manufacturing and industrial machinery

- Construction and bulk material handling

- Cement, steel, and other heavy industry sectors

Resources