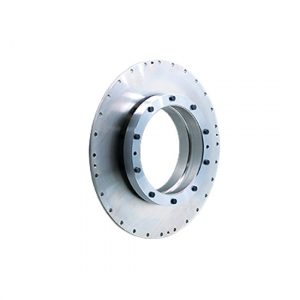

Ringspann Shaft-Hub Connections

Secure, precise, and durable connections with excellent torque transmission for industrial applications.

Featured Products

Resources

We use cookies to ensure that we give you the best experience on our website. If you continue to use this site we will assume that you are happy with it.

Secure, precise, and durable connections with excellent torque transmission for industrial applications.

For the frictional connection of torque motors to machine shafts.

Designed to suit various torque capacities and installation requirements.

Backlash-free, high-torque shaft-hub connections for hollow shafts or hubs, ensuring easy assembly and compact drives.

Precise, backlash-free shaft-hub clamping and axial preloading for smooth, quiet bearing operation.

Please contact us using the form below or send us an email.