Reich TOK Docking System

Increase the efficiency of engine test benches by higher productivity, shorter set-up times and lower operating costs.

More productivity, shorter set-up times, lower operating costs – the new REICH docking system will increase the efficiency of engine test benches.

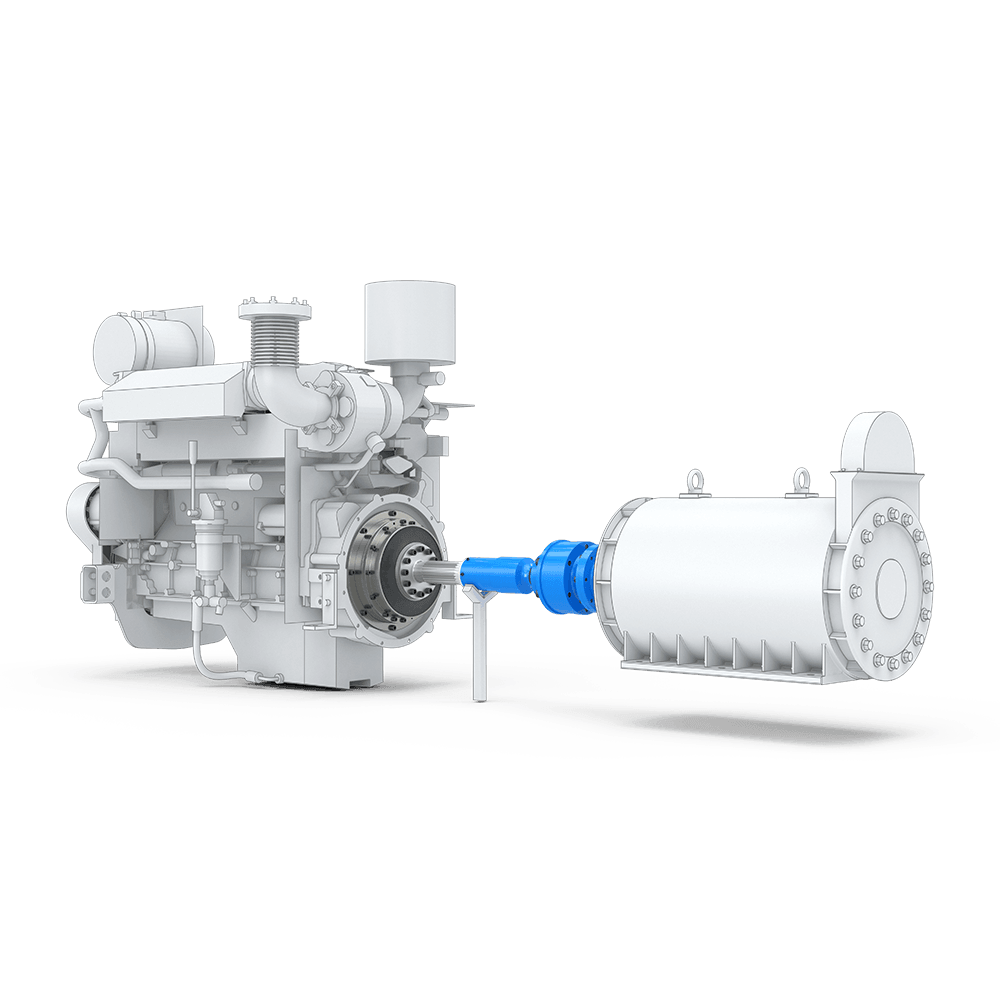

The aim of the system is to largely automate the change of test specimen when testing internal combustion engines. The time available for testing is thus maximised. This is made possible by a docking system which is based on the principle of modular construction. It is used to connect combustion engines of different sizes to a dynamometer. This way, engine testing is made easy.

Flexible docking and centering fixture

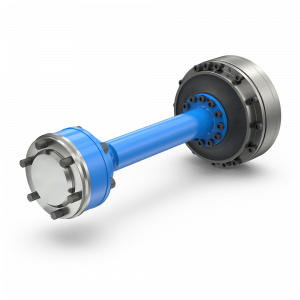

The special feature of the docking system is its self-docking and self-centering fixture. It consists of a pin and a sleeve which are both straight-toothed. The two components are available in a standard size and mounted to a coupling matching the engine to be tested.

Rigging additional engines while testing

This fixture allows for preparing other engines to be tested while one engine is still undergoing testing. Rigging only involves the mounting of the matching coupling with the standard pins to the engine. Given that this work is performed outside the test bench area, rigging times are minimised in the test cell.

Self-alignment and self-centering

The smart design of the centering attachments allows them to compensate for an offset of up to 15 mm while docking. While the engine with the mounted TOK coupling and toothed pins is slowly approaching its destination, the CV-jointed sleeve on the dynamometer side rests on a support.

While docking, the sleeve is lifted off the centering attachment and turned until the toothed components engage.

Advantages

- There is no longer need for complex mechanics and manual intervention on the dynamometer side.A correctly positioned, solid support is sufficient

- Rigging with time-consuming assembly procedures takes place outside the test cell

- Rotational speeds of up to 6 000 -rpm are possible

- All the toothed shaft components of a system engage in any turning position while maintaining good balance

- Centering attachments are available as spare parts and easily changeable

- The docking system can be extended to multiple test cells

Type D2C – Designed to Customer

- Couplings individually developed according to customer requirements

- Effective and efficient customer solutions through largely modular components

- Close cooperation with our partners: consulting, development, design, manufacturing, integration

- Customer-specific production and logistics concepts, as well as after-sales service

- Global availability

- For standard products as well as for production in small batch sizes.

Videos

Resources

Other Reich Products