New Turbostart Industrial Brakes

Playing a crucial role in various industries, Industrial Brakes ensure safe and controlled operation of heavy machinery.

Industrial brakes, whether drum brakes or disc brakes, are essential components and play a crucial role in various industries, ensuring the safe and controlled operation of heavy machinery and equipment.

Applications

Drum Brakes

- Conveyors

- Process lines

- Excavators

- Cranes

- Winches and Hoists

- Elevators and Lifts

- Industrial Machinery

- Port Machinery

Disk Brakes

- Wind Turbines

- Mining Equipment

- Industrial Presses

- Railways

- Heavy Machinery

Industries

Drum Brakes

- Automation

- Concrete & Construction

- Industrial

- Marine

- Mining & Heavy Industry

- Transportation

Disk Brakes

- Industrial

- Mining & Heavy Industry

- Oil and Gas

- Renewable Energy

- Transportation

Features & Benefits

- Reliable Braking Performance: Ensuring precise control and stopping power for heavy machinery and equipment.

High Load Capacity: Suitable for applications where substantial braking force is needed. - Robust Construction: Built to withstand harsh operating conditions, including high temperatures, vibrations, and exposure to dust, dirt, and moisture.

- Adjustable Braking Force: Allowing operators to customize the braking performance based on the specific requirements of the application.

- Quick Response Time: Ensuring quick response times when braking is required. This feature enhances safety and operational efficiency.Low Maintenance: Are engineered for reliable performance over extended periods without frequent servicing.

- Safety Features: Such as fail-safe mechanisms, emergency braking systems, and manual release options to ensure safe operation and prevent accidents.

- Noise and Vibration Damping: Improving operator comfort and reducing noise pollution in the workplace.

- Versatility: Industrial brakes are available in various configurations and sizes, making them adaptable for a wide-range of applications and industries.

Products

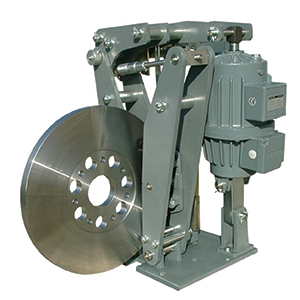

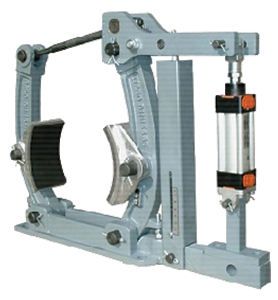

Industrial Drum Brake NC

| Brake type | Braking torque Nm | Dimensions in mm | Weight Kg. | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| D | A | B | C | d | F | G | h | Hma x. | L | K | M | P | S | |||

| NC200-Th1 | 230 | 200 | 115 | 145 | 55 | 14 | 55 | 70 | 160 | 430 | 90 | 422 | 142 | 165 | 12 | 25 |

| NC200-Th2 | 310 | 200 | 115 | 145 | 55 | 14 | 55 | 70 | 160 | 470 | 90 | 450 | 168 | 165 | 12 | 30 |

| NC250-Th1 | 260 | 200 | 144 | 180 | 62 | 18 | 65 | 90 | 190 | 485 | 100 | 476 | 142 | 208 | 14 | 38 |

| NC250-Th2 | 350 | 250 | 144 | 180 | 62 | 18 | 65 | 90 | 190 | 485 | 100 | 501 | 168 | 208 | 14 | 43 |

| NC250-Th3 | 700 | 250 | 144 | 180 | 62 | 18 | 65 | 90 | 190 | 500 | 100 | 510 | 192 | 208 | 14 | 45 |

| NC315-Th1 | 285 | 315 | 189 | 220 | 68,5 | 18 | 80 | 110 | 230 | 532 | 120 | 536 | 174 | 257,5 | 15 | 48 |

| NC315-Th2 | 425 | 315 | 189 | 220 | 68,5 | 18 | 80 | 110 | 230 | 532 | 120 | 593 | 168 | 257,5 | 15 | 53 |

| NC315-Th3 | 850 | 315 | 189 | 220 | 68,5 | 18 | 80 | 110 | 230 | 532 | 120 | 601 | 192 | 257,5 | 15 | 55 |

| NC315-Th3.75 | 1050 | 315 | 189 | 220 | 68,5 | 18 | 80 | 110 | 230 | 532 | 120 | 601 | 192 | 257,5 | 15 | 55 |

| NC315-Th4 | 1700 | 315 | 189 | 220 | 68,5 | 18 | 80 | 110 | 230 | 565 | 120 | 618 | 234 | 257,5 | 15 | 62 |

| NC400-Th2 | 525 | 400 | 240 | 270 | 74 | 22 | 100 | 140 | 280 | 668 | 150 | 687 | 168 | 314 | 17 | 79 |

| NC400-Th3 | 1040 | 400 | 240 | 270 | 74 | 22 | 100 | 140 | 280 | 668 | 150 | 695 | 192 | 314 | 17 | 81 |

| NC400-Th3.75 | 1300 | 400 | 240 | 270 | 74 | 22 | 100 | 140 | 280 | 668 | 150 | 695 | 192 | 314 | 17 | 81 |

| NC400-Th4 | 2075 | 400 | 240 | 270 | 74 | 22 | 100 | 140 | 280 | 668 | 150 | 715 | 234 | 314 | 17 | 88 |

| NC500-Th4 | 2500 | 500 | 295 | 325 | 85 | 22 | 130 | 180 | 340 | 760 | 170 | 812 | 234 | 380 | 20 | 130 |

| NC500-Th5 | 4170 | 500 | 295 | 325 | 85 | 22 | 130 | 180 | 340 | 785 | 170 | 823 | 274 | 380 | 20 | 153 |

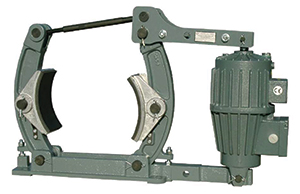

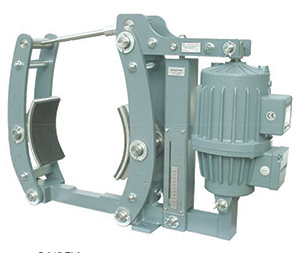

Industrial Drum Brake ST

| Brake type | Thrustor type ELCO | Max torque in Nm =0,4 | Dimensions (mm) | Weight without thrustor kg | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| D | a | b | c | d | e | f | g | h | H max | k | L | m | p | t | ||||

| ST 200 ST 200 |

Th 1 Th 2 |

250 330 |

200 | 115 | 145 | 50 | 14 | 20 | 55 | 70 | 160 | 405 492 |

417 453 |

92 | 142 168 |

170 | 10 | 24 |

| ST 250 ST 250 ST 250 |

Th 1 Th 2 Th 3 |

300 400 750 |

250 | 145 | 180 | 60 | 18 | 25 | 65 | 90 | 190 | 525 | 483 508 516 |

110 | 142 168 192 |

212 | 12 | 32 |

| ST 315 ST 315 ST 315 |

Th 1 Th 2 Th 3 Th 4 |

350 480 950 1800 |

315 | 180 | 220 | 70 | 18 | 30 | 80 | 110 | 230 | 586 | 553 578 586 605 |

120 | 142 168 192 234 |

263 | 12 | 48 |

| ST 400 ST 400 ST 400 |

Th 2 Th 3 Th 4 |

680 1300 2500 |

400 | 230 | 270 | 70 | 22 | 30 | 100 | 140 | 280 | 702 | 665 673 692 |

150 | 168 192 234 |

314 | 15 | 85 |

| ST 500 ST 500 ST 500 |

Th 3 Th 4 Th 5 |

1600 3100 5120 |

500 | 285 | 325 | 80 | 22 | 40 | 130 | 180 | 340 | 833 | 803 822 833 |

180 | 192 234 274 |

395 | 15 | 150 |

| ST 630 ST 630 ST 630 |

Th 4 Th 5 Th 6 |

3100 5000 7200 |

630 | 340 | 400 | 95 | 27 | 40 | 170 | 225 | 420 | 1010 | 898 909 909 |

250 | 234 274 274 |

468 | 20 | 210 |

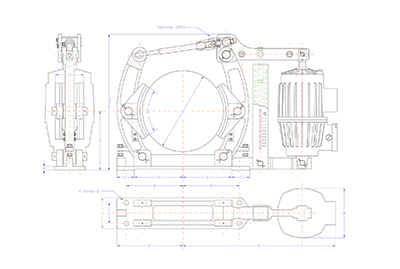

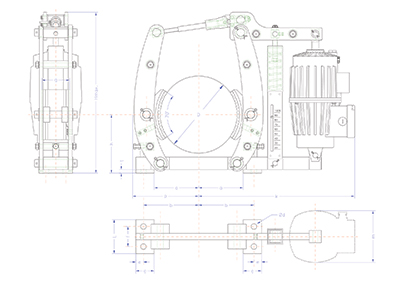

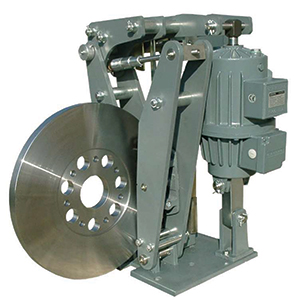

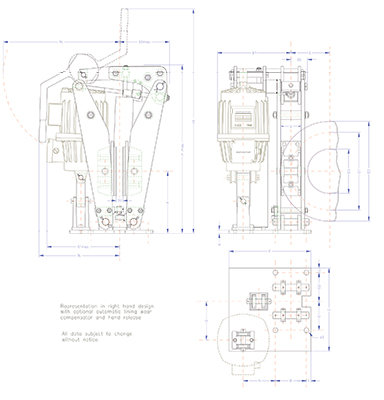

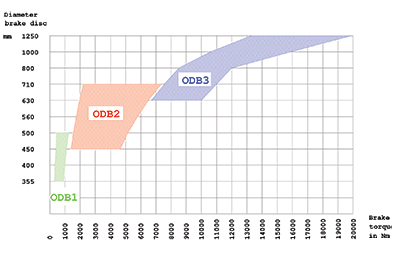

Industrial Disk Brake ODB

ODB 1

| A2 | B | B2 | C | d3 | F | G1 | G2 | h | h max | k | L | N | P | S | V |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 225 | 140 | 75 | 375 | 22 | 370 | 130 | 130 | 280 | 800 | 15 | 20 | 145 | 20 | 1,1 | 90 |

|

|

Thrustor ELCO Type | |||||||||||||

Brake disc |

Th3 | Th4 | Th5 | ||||||||||||

| D2 | D1 | D3 | E | Braking torque in Nm at = 0,4 | |||||||||||

| 450 | 350 | 200 | 175 | 1400 | 2800 | 4650 | |||||||||

| 500 | 400 | 250 | 200 | 1550 | 3100 | 5150 | |||||||||

| 560 | 460 | 310 | 230 | 1750 | 3450 | 5800 | |||||||||

| 630 | 530 | 380 | 265 | 1950 | 3900 | 6500 | |||||||||

| 710 | 610 | 460 | 305 |

|

|

2200 | 4400 | 7350 | |||||||

| Weight brake without thrustor Kg.111 | Dimensions depending on thrustor size | ||||||||||||||

| A1 max | 327 | 348 | 377 | ||||||||||||

| B1 | 311 | 332 | 354 | ||||||||||||

| HL | 1088 | 1020 | 1276 | ||||||||||||

| RL | 540 | 542 | 746 | ||||||||||||

| BL | 358 | 371 | 413 | ||||||||||||

| Q | 175 | 175 | 195 | ||||||||||||

ODB 2

A2 |

B |

B2 |

C |

d3 |

F |

G1 |

G2 |

h |

h max |

k |

L |

N |

P |

S |

V |

225 |

140 |

75 |

375 |

22 |

370 |

130 |

130 |

280 |

800 |

15 |

20 |

145 |

20 |

1,1 |

90 |

|

|

Thrustor ELCO Type |

|||||||||||||

Brake disc |

Th3 |

Th4 |

Th5 |

||||||||||||

D2 |

D1 |

D3 |

E |

Braking torque in Nm at = 0,4 |

|||||||||||

450 |

350 |

200 |

175 |

1400 |

2800 |

4650 |

|||||||||

500 |

400 |

250 |

200 |

1550 |

3100 |

5150 |

|||||||||

560 |

460 |

310 |

230 |

1750 |

3450 |

5800 |

|||||||||

630 |

530 |

380 |

265 |

1950 |

3900 |

6500 |

|||||||||

710 |

610 |

460 |

305 |

|

|

2200 |

4400 |

7350 |

|||||||

Weight brake without thrustor Kg.111 |

Dimensions depending on thrustor size |

||||||||||||||

A1 max |

327 |

348 |

377 |

||||||||||||

B1 |

311 |

332 |

354 |

||||||||||||

HL |

1088 |

1020 |

1276 |

||||||||||||

RL |

540 |

542 |

746 |

||||||||||||

BL |

358 |

371 |

413 |

||||||||||||

Q |

175 |

175 |

195 |

||||||||||||

ODB 3

| A2 | B | B2 | C | d3 | F | G1 | G2 | h | h max | k | L | N | P | Q | S | V |

| 235 | 160 | 95 | 460 | 27 | 410 | 180 | 180 | 370 | 1050 | 20 | 50 | 155 | 30 | 195 | 1 | 120 |

Thrustor ELCO Type |

||||||||||||||||

Brake disc |

Th 5 | Th 6 | ||||||||||||||

| D2 | D1 | D3 | E | Braking torque in Nm at = 0,4 |

||||||||||||

| 630 | 500 | 310 | 250 | 6700 | 10000 | |||||||||||

| 710 | 580 | 390 | 290 | 7550 | 11300 | |||||||||||

| 800 | 670 | 480 | 335 | 8500 | 12750 | |||||||||||

| 1000 | 870 | 680 | 435 | 10600 | 15900 | |||||||||||

| 1250 | 1120 | 930 | 560 | 13300 | 19900 | |||||||||||

| Weight brake without thrustor Kg.220 Dimensions in millimeters D1 theoretic friction diameter S air gap |

Further dimensions | |||||||||||||||

| A1 max | 395 | |||||||||||||||

| B1 | 372 | |||||||||||||||

| HL | 1525 | |||||||||||||||

| RL | 745 | |||||||||||||||

| BL | 418 | |||||||||||||||

Resources