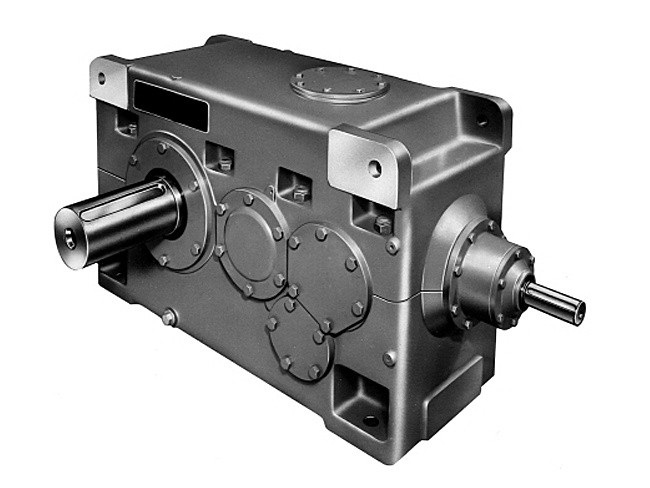

Radicon H Series Heavy Industry Gearbox

Series H Inline Industrial gearboxes are available in parallel and right angle versions in single, double, triple and quadruple reduction gear stages.

The modular design and construction of the Series H offers many engineering and performance benefits including a high degree of interchange ability of parts and sub assemblies. This in turn provides considerable economies of production while maintaining the highest standard of component integrity.

Gear tooth geometry design combines maximum efficiency with high load carrying capacity and minimal noise generation. Serviceability of the product was key in the design of the Series H range allowing easy maintenance for long life and reliability, which are synonymous with our field reputation.

Features

- Available in inline and right angle configurations

- Offered in single, double, triple, and quadruple reduction stages

- Modular design for high interchangeability of parts

- Hollow bore and shrink disc options gives versatility in mounting

- Large diameter output shaft, higher over hung loads

- Lip, Labyrinth and Face Seal on input, Lip Seal and Labyrinth on output shaft

- Vertical units have a Drywell sealing arrangement

Benefits

- Best option for stirrer applications

- Better sealing for harsher environments

- Hollow bore reduces alignment issues

- No head of oil resting on the output seal

- Provides longer life

- Reduced down time

| Unit Sizes | 140, 160, 180, 200, 225, 250, 280, 315, 355, 400, 450 |

|---|---|

| Input Power | Up to 8,300 kW (11,122 HP) |

| Torque Rating | Up to 117,000 Nm (1,035,450 lb.in.) |

| Gear Ratios | Up to 130:1 |

Resources