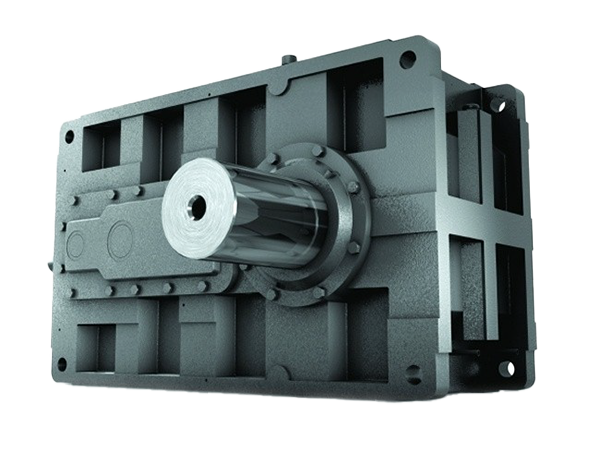

Radicon G Series Helical Industrial Gearbox

Case-hardened helical gears, optimised geometry for strength, low noise & vibration. Horizontal split case for easy maintenance, large output shaft and bearings for maximum overhung load capacity.

With high-quality materials and components, the Series G includes; case-hardened and ground helical gears and hard-optimised gear geometry to maximise strength and efficiency, and to minimise noise and vibration. Horizontal split case design for ease of maintenance and a large diameter output shaft and bearings to maximise overhung load capacity.

The Series G helical industrial gearboxes have been introduced to meet the requirements of today’s demanding applications in the medium and heavy-duty sector of the power transmission market. Innovative modular design technology has minimised manufactured part count to maximise availability of product.

Gear tooth geometry design combines maximum efficiency with high load carrying capacity and minimal noise generation. Serviceability of the product was key in the design of the Series G range allowing easy maintenance for long life and reliability, which are synonymous with our field reputation.

A range of motor adaptors are available for alignment free motor fitment, units can also be supplied fully assembled on a fabricated steel baseplate.

Features

- Hollow bore and shrink disc options gives versatility in mounting

- Large diameter output shaft, higher over hung loads

- Lip, Labyrinth and Face Seal on input, Lip Seal and Labyrinth on output shaft

- Vertical units have a Drywell sealing arrangement

Benefits

- Best option for stirrer applications

- Better sealing for harsher environments

- Hollow bore reduces alignment issues

- No head of oil resting on the output seal

- Provides longer life

- Reduced down time

| Unit Sizes | 14, 15, 16, 17, 18, 19, 21 and 22 |

|---|---|

| Input Power | Up to 1,860 kW (2,494 HP) |

| Torque Rating | Up to 162,000 Nm (1,433,821 lb.in.) |

| Gear Ratios | Up to 315:1 in multistage and up to 70,000:1 in combined form |

| Output Shaft | Up to 240mm (9.45 in.) |

| Motor Sizes | IEC Frames from 200 to 315; NEMA Frames from 254 to 445 |

Resources