D.I.D Environmental Chains

A diverse range of environmentally resistant Chains that excel even in the most demanding conditions.

DID offers a diverse range of anti-corrosion chains and specialty options for customers prioritizing corrosion resistance in their working environments. DID’s Environment Resistant Chains excel even in demanding conditions.

Products

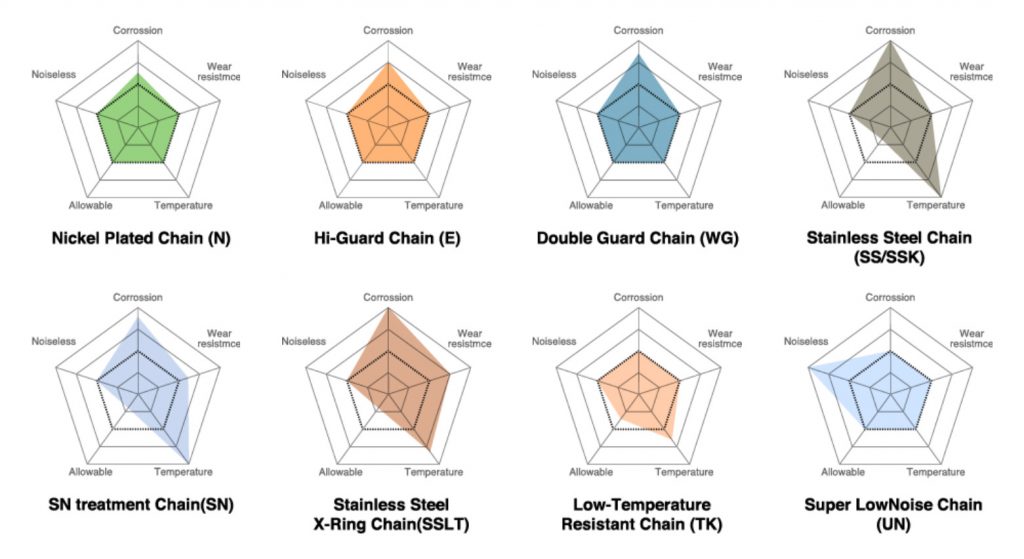

Nickel Plated Chain (N)

- Neat, Clean and Glossy Finish and decent corrosion resistance.

- Nickel plating is coated to each component before assembly.

- Use Hi-Guard or Double Guard chains when used in severe corrosive conditions and strength is required.

Hi-Guard Chain (E)

- Rust protection is “Twice as Tough” as Nickel Plated thanks to highly corrosion resistant film.

- Compliant to RoHS and using environmental friendly material.

- Recommended for the application where both strength and high corrosion resistance are required.

- Use Stainless Steel chains when chains are expected to contact with food.

Double Guard Chain (WG)

- Rust protection is “Twice as Tough” as Hi-Guard Chain thanks to Double Layer Special Coating.

- Compliant to RoHS and using environmental friendly material.

- Can be used in mild alkaline and mild acid conditions.

- Use Stainless Steel chains when chains are expected to contact with food.

Stainless Steel Chain (SS/SSK)

- SS series Stainless Steel chain is assembled with all components being made of SUS304

- SS chains provide excellent resistance to corrosion and heat.

- DID’s SS chains comes with seamless SOLID ROLLER.

- SSK series Stainless Steel chain consists of SUS304 link plates and hardened SUS631 round parts.

- Maximum Allowable Load from SSK is higher by 50% than the one from SS.

SN treatment Chain (SN)

- SN chain has the same strength as that of regular carbon steel chain thanks to the heat reatment over 13Cr stainless steel (SUS400 series).

- SN also provides unique surface treatment, which can be expected to have the same corrosion resistant performance as SUS600.

- SN treatment forms hardening layer, resulting in better wear resistance.

Stainless Steel X-Ring Chain (SSLT)

- Combination of advantages from Stainless Steel Chain and X-Ring Chain.

- Chain Grease sealed between pin and bushing is food grade.

- X-Ring material is heat resistant up to 200℃ (392°F)

- Size available in 40 through 80.

Low-Temperature Resistant Chain (TK)

- Can be used at cold environment where temperature reaches down to -40℃(-40°F)

- Excellent Strength at Low Temperature thanks to special material and grease.

Super Low Noise Chain (UN)

- Reducing the noise up to 10dB thanks to unique double layer roller.

- Drive performance and durability are equivalent to DID standard chain

- Standard sprocket and connecting link can be used.

- Size available in 40 through 80.

Resources