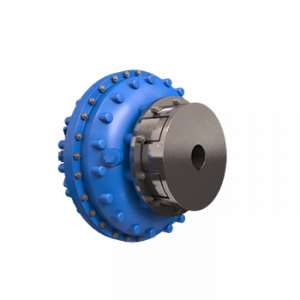

Fluid Couplings

Also known as hydraulic couplings, they provide a smooth shock-free transfer of torque from one shaft to another shaft by means of acceleration and deceleration of a hydraulic fluid.

Fluid couplings protect your machinery and ensure a longer life for your equipment as they comprise of three main elements including the Driving impeller (pump) mounted on the input shaft, the Driven impeller (turbine) mounted on the output shaft and the Cover, flanged to the outer impeller, with an oil-tight seal. The first two elements can work both as pump or turbine.

Used for industrial machine drives, they are a highly efficient as they provide shock-free start-up for the power transmission system, protecting surrounding equipment. Designed to withstand harsh environments and challenging operating conditions.

The fluid couplings are available with delay fill chamber and can be supplied as bare-shaft or fitted with v-belt pulley drives.

Benefits

- The power transmission is free from vibration and noises

- Power transmission is smooth even in extreme conditions

- Shock-free start up

- Maximum torque can be adjusted by varying the amount of oil filled in the casing

- Fluid couplings can be used in both vertical and horizontal applications.

- Overload protection

Featured Products

Resources