Ringspann Clamping Systems for Torque Motors

For the frictional connection of torque motors to machine shafts.

Applications

- Gearboxes, couplings and electric motor drives

- Pulleys, sprockets, brake discs, flywheels

- Conveyors, belt drives, drums, rollers

- Adjustable machine tools, positioning systems

- Systems where frequent clamping/unclamping is required (for which Star Discs are especially suited)

Benefits

- Backlash-free transmission — eliminates play and ensures precise torque transfer.

- Multi-force capability — able to transmit torque, axial force, radial load and bending moments simultaneously.

- Compact and efficient design — allows for smaller shafts and shorter lengths compared to conventional keyway solutions.

- Non-destructive release — clamping elements can be released even after extended operating periods.

- Precise centring — ensures optimal alignment between hub and shaft.

- Reliable sizing via calculation tool — the RINGSPANN Calculation Method and online tool help avoid over- or under-design.

RINGSPANN Shaft-Hub Connections provide a modern, friction-locked alternative to traditional keyed or splined connections. Designed for precision, performance and reliability, these elements enable secure and backlash-free transmission of torque between shafts and hubs — ensuring maximum efficiency and minimal wear.

Unlike conventional methods that rely on positive-fit keys, RINGSPANN connections transmit torque purely through friction across the entire contact surface. This eliminates play, reduces stress concentrations, and allows smaller shaft diameters or shorter hub lengths to be used without compromising strength or stability.

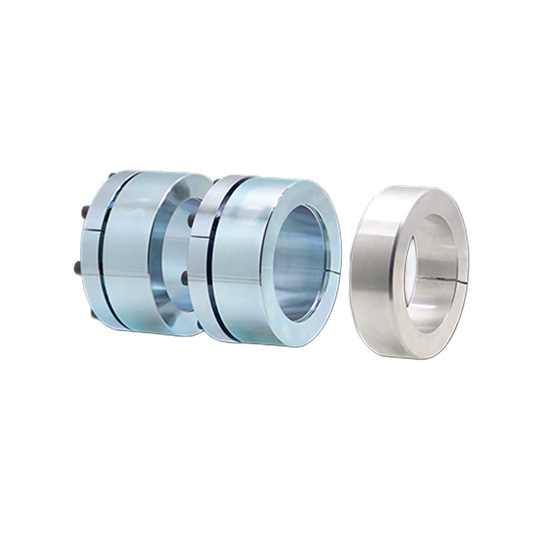

Each system is engineered to deliver uniform radial clamping pressure, guaranteeing precise centring and smooth torque transfer even under dynamic loads. Whether using Shrink Discs, Cone Clamping Elements, or Star Discs, RINGSPANN’s range offers proven solutions for both external and internal clamping applications.

Built for high-performance industrial environments, these connections combine robust mechanical design with easy installation and non-destructive removal. They are suitable for shafts ranging from small precision drives to large heavy-duty systems, with transmissible torques reaching up to several million newton-metres.

Ringspann Clamping Systems for Intergrated Torque Motors

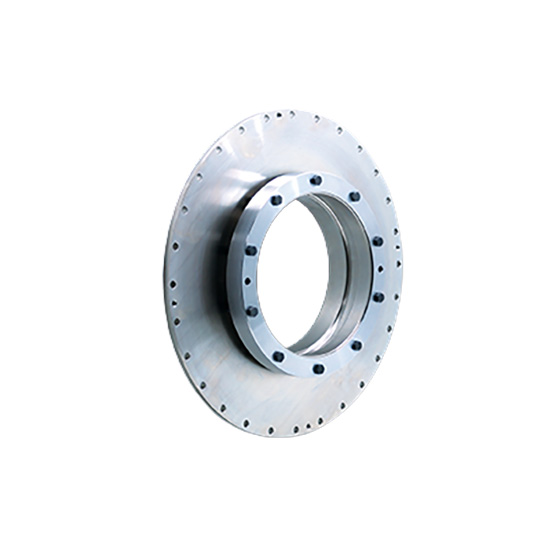

Ringspann Clamping Systems for SIEMENS Complete Torque Motors 1FW3

Ringspann Clamping Systems for Complete Torque Motors

Resources