Taper Lock Bushes

Also called a taper lock bore, taperlock bush or taper fit bush, allow a driven device, such as a couplings, pulley, sprocket or sheave, to be fixed onto a shaft. The split and tapered design provides a powerful clamp fit whilst being easy to install and dismantle, saving on machining costs and avoiding delays.

Used for the mechanical joining of a shaft to a sprocket or a pulley. Taper lock bushes are fastened securely to a shaft via the tapered surface, providing flexibility between the main component to be suitable with many shaft sizes.

Taper Lock Bushes come in a variety of bore sizes, in both metric and imperial. Locking Assemblies provide reliable, high strength keyless connections by converting locking screw clamp loads into radial contact pressures applied simultaneously to both the shaft and the bore of the mounted component.

The resulting zero-backlash mechanical interference fit will accommodate high torque, thrust, bending and/or radial loads and unlike other mounting technologies will never wear or pound out, even for high cycle fluctuating or reversing loads. Locking Assemblies also provide reliable, high strength keyless connections for shaft driven devices. When the Locking Units bolts are tightened plates engage with both the shaft and the inside circumference of the driven component.

The Locking Assembly distributes the applied pressure evenly. No keyways or grubscrews are required with this device. The simple design allows for easy maintenance, has an easy-on, easy-off process.

Materials

- Cast iron

- Stainless Steel

Systems of Measurment

- Metric

- Imperial

Applications

- Couplings

- Pulleys

- Sprockets

- Sheaves

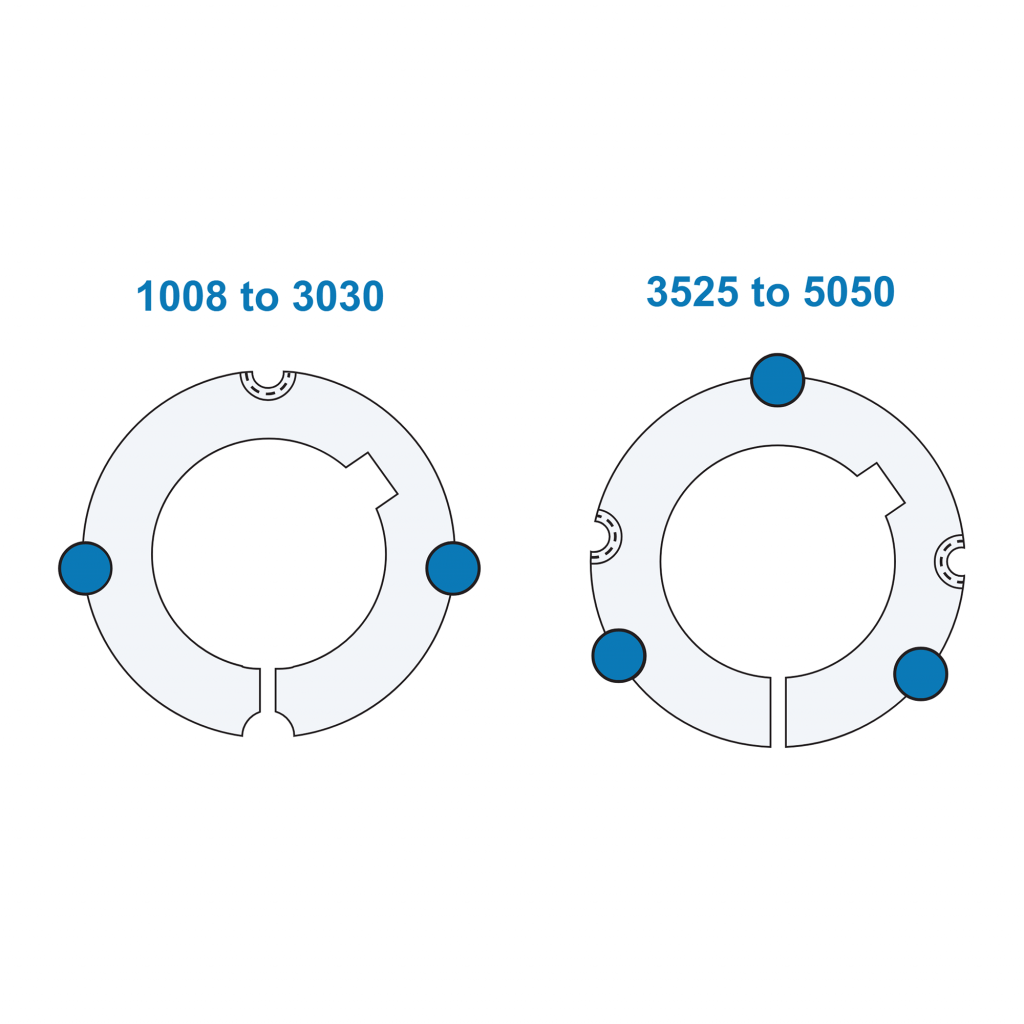

| Bush Size | Ø T | LBT | UTS 200 N/mm2 Gray Iron | Minimum HUB Diameter H UTS 250 N/mm2 Gray Iron | UTS 420 N/mm2 Steel | Ø B | Quantity Screws | S Set Screws Size (Inches) | K |

|---|---|---|---|---|---|---|---|---|---|

| 1008 | 35.20 | 22.3 | 59 | 54 | 51 | 33.73 | 2 | 1/4 x 1/2 | – |

| 1108 | 38.38 | 22.3 | 61 | 57 | 54 | 36.92 | 2 | 1/4 x 1/2 | – |

| 1210 | 47.62 | 25.4 | 99 | 86 | 78 | 44.44 | 2 | 3/8 x 5/8 | – |

| 1215 | 47.62 | 38.1 | 79 | 73 | 68 | 44.44 | 2 | 3/8 x 5/8 | – |

| 1310 | 50.80 | 25.4 | 100 | 88 | 80 | 47.63 | 2 | 3/8 x 5/8 | – |

| 1610 | 57.15 | 25.4 | 102 | 92 | 85 | 53.97 | 2 | 3/8 x 5/8 | – |

| 1615 | 57.15 | 38.1 | 86 | 81 | 77 | 53.97 | 2 | 3/8 x 5/8 | – |

| 2012 | 69.85 | 31.8 | 115 | 106 | 99 | 66.68 | 2 | 7/16 x 7/8 | – |

| 2517 | 85.73 | 44.5 | 125 | 119 | 113 | 82.55 | 2 | 1/2 x 1 | – |

| 2525 | 85.73 | 63.5 | 115 | 111 | 108 | 82.56 | 2 | 1/2 x 1 | – |

| 3020 | 107.96 | 50.8 | 154 | 146 | 140 | 101.60 | 2 | 5/8 x 1.1/4 | – |

| 3030 | 107.96 | 76.2 | 141 | 136 | 132 | 101.60 | 2 | 5/8 x 1.1/4 | – |

| 3525 | 127.00 | 63.5 | 206 | 191 | 178 | 122.68 | 3 | 1/2 x 1.1/2 | 40° |

| 3535 | 127.00 | 89.0 | 185 | 176 | 168 | 122.68 | 3 | 1/2 x 1.1/2 | 40° |

| 4030 | 146.05 | 76.2 | 220 | 207 | 197 | 140.72 | 3 | 5/8 x 1.3/4 | 40° |

| 4040 | 146.05 | 101.5 | 203 | 195 | 188 | 140.72 | 3 | 5/8 x 1.1/4 | 40° |

| 4535 | 161.93 | 89.0 | 221 | 212 | 205 | 455.70 | 3 | 3/4 x 2 | 40° |

| 4545 | 161.93 | 114.3 | 211 | 205 | 200 | 155.70 | 3 | 3/4 x 2 | 40° |

| 5040 | 177.80 | 101.6 | 236 | 229 | 223 | 170.69 | 3 | 7/8 x 2.1/4 | 37° |

| 5050 | 177.80 | 127.0 | 230 | 223 | 219 | 170.69 | 3 | 7/8 x 2.1/4 | 37° |

Resources

Related Products

Contact us about Taper Lock Bushes