Ringspann Overload Clutches

Ringspann Overload Clutches ensure equipment safety and durability by disengaging during torque overloads, ideal for heavy-duty machinery and conveyor systems.

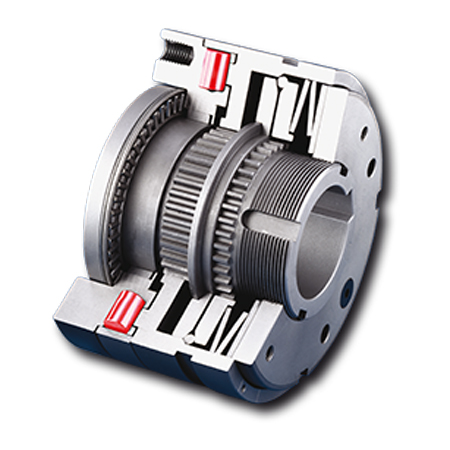

Positive Torque Limiters

Ratcheting – SIKUMAT® SC/SG/ST

Features

- Backlash free in both directions of rotation

- Compact design

- Integral ball bearing for supporting the component to be connected

- Very high response accuracy through the ball principle

- Simple and backlash free fastening onto shaft with integral cone clamping element

- Calibrated micro adjustment of torque setting possible, even post-installation

Function

- When the preset limit torque has been reached the SIKUMAT® ratchets through.

- Automatic re-engagement of the SIKUMAT® after the overload has been eliminated.

- The overload can be indicated by a proximity switch. This means that the drive can be switched off immediately or another control function can be activated.

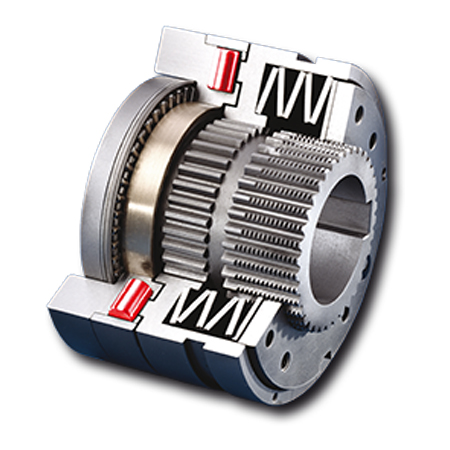

Synchronous Ratcheting – SIKUMAT® SU/SA/SN

Features

- Synchronous re-engagement after 360°

- Integral fixed bearing

- Driving keyway in the connecting flange for maximum load capacity

- Calibrated micro adjustment of torque setting possible, even post-installation

- Cost effective

Function

- When the preset limit torque has been reached the SIKUMAT® ratchets through.

- Automatic re-engagement of the SIKUMAT® after the overload has been eliminated.

- The overload can be indicated by a proximity switch. This means that the drive can be switched off immediately or another control function can be activated.

Disengaging – SIKUMAT® SR

Features

- Disengages in case of overload – separation of input and output

- Integral fixed bearing

- Keyway in connecting flange for maximum torque capacity

- Calibrated micro adjustment of torque setting possible, even post-installation

- Cost effective

Function

- When the preset limit torque has been reached the SIKUMAT® disengages the input and output.

- After the overload has been eliminated the SIKUMAT® can be switched on again manually.

- This means that an axial switching force must be applied to the switching ring.

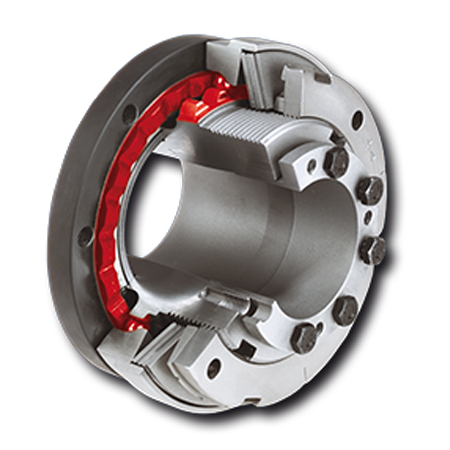

Synchronous Disengaging – SIKUMAT® SB

Features

- High degree of consistency of limit torque over the duration of operation through double roller principle

- Switching off in case of overload – separation of input and output

- Synchronous re-engagement after 360°

- Torques up to 10 000 Nm

- For shaft diameters up to 125 mm

Function

- When the preset limit torque has been reached the SIKUMAT® effects a separation of input and output by means of a locking mechanism with integral bearings.

- Following elimination of the overload manual synchronous re-engagement of the SIKUMAT® to the starting position after 360°.

- This requires an axial switching force to be applied to the switching ring.

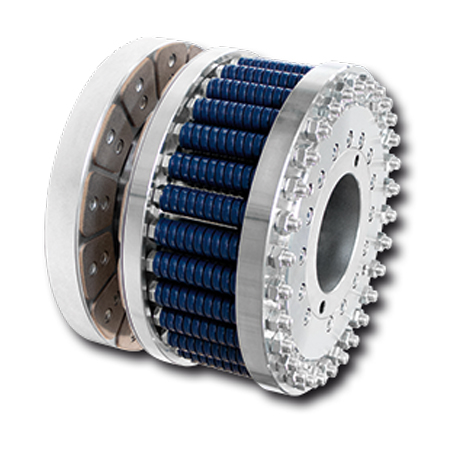

Friction Torque Limiters

RIMOSTAT® Torque Limiters RSHD – for heavy-duty applications

Features

- Better stability of slipping torque than Belleville spring torque limiters over duration of the operating period

- Adjustment of slipping torque setting according to the number of active springs – not through modification of spring pressure

- Superb wear-behaviour during high energy-input

- High temperature resistant

RIMOSTAT® Torque Limiters RS

Features

- Particularly suitable in applications with frequent slipping

- Better stability of slipping torque than Belleville spring torque limiters over duration of the operating period

- Adjustment of slipping torque setting according to the number of active springs – not through modification of spring pressure

Function

- When the preset slipping torque has been reached the built-in component (e. g. chain wheel) slips.

- During the slipping process, input and output rotate relative to each other and the preset slipping torque continues to be transmitted.

- Inherent in the slipping process is a high energy consumption.

- Re-engagement is not necessary.

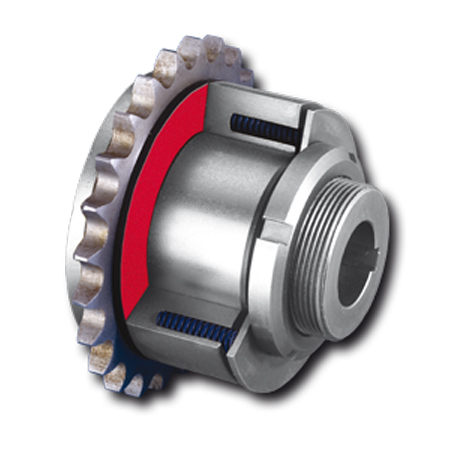

Belleville Spring Torque Limiters RT

Features

- Cost effective, simple Torque Limiter

- Adjustment option for pad wear

- 12 Sizes for slipping torques from 0.5 Nm to 10 000 Nm

Function

- When the preset slipping torque has been reached the built-in component (e. g. chain wheel) slips.

- During the slipping process, input and output rotate relative to each other and the preset slipping torque continues to be transmitted.

- Inherent in the slipping process is a high energy consumption.

- Re-engagement is not necessary.

Force Limiters

Resources