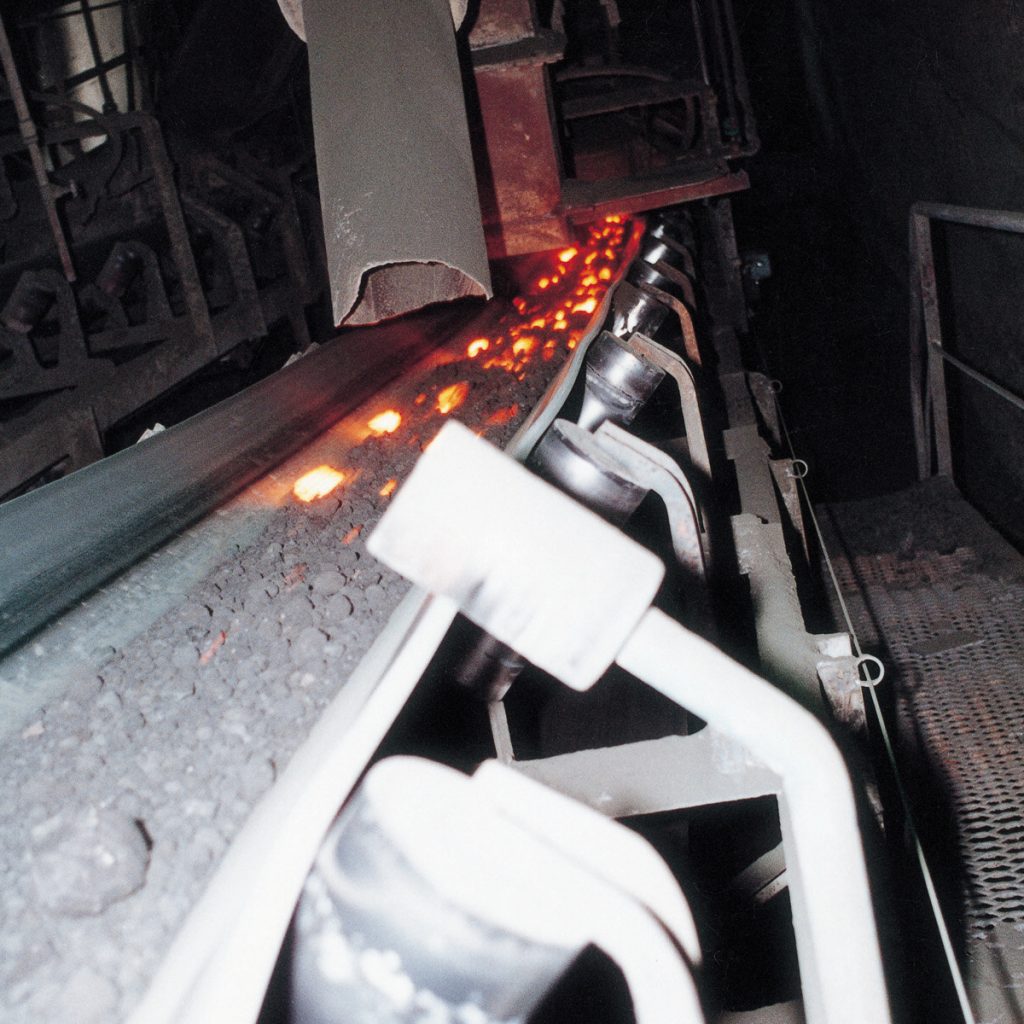

Bando Heat Carry™ Conveyor Belts

Bando’s ultra-high heat and abrasion resistant conveyor belt lineup is specifically designed and compounded to yield exceptionally long service life. Bando Heat Carry™ Conveyor Belts are used in applications where extreme material temperatures (up to 850°F) are expected and wear resistant product is a must.

Features

- Superior resistance to heat and abrasion

- Molded edged belts manufactured to width

- Dependable vulcanized splices

Applications

- Cement plants (clinker, cement products, dry clay, etc.)

- Steel mills (sintered ore, coke, pellets, slag, etc.)

- Foundries

- Taconite

Performance

- Handles material temperatures up to 850°F

- Superior adhesion between the cover rubber and core body when exposed to heat

- Lasts up to 50% longer than conventional heat-resistant belt

Specification

| Belt Type | Features | Material Temperature | Allowable Belt Surface Temperature | Major Applications |

|---|---|---|---|---|

| HC-770 | Superior wear and heat-ageing resistance | Powder: Up to 350o F Bulk: Up to 850o F | 350o F | Clinker Coke Dried Clay Dried Lime Sintered Ore Products Taconite |

| HC-1500 | Premium wear and heat-ageing resistance Service life twice as long as conventional heat belts | Powder: Up to 400o F Bulk: Up to 850o F | 400o F | Clinker Coke Sintered Ore Products Taconite |

| HC-730 | White belt used for lines averse to contamination of products | Powder: Up to 270o F Bulk: Up to 600o F | 270o F | Soda Ash Fertilizers Raw Materials White Cements |

《Applications that must be avoided》

1. Applications that must be avoided for all heat-resistant conveyor belts

・Avoid materials that contain or have on their surface other oils than vegetable oil even a little.

・Avoid applications that require flame resistance.

2. Applications that must be avoided for Heat Carry HC-710, HC-730, and HC-770 conveyor belts

・Avoid conveying powder materials at 180ºC or higher.

Videos

Resources