Unlock the Secret to Chain Longevity: The Ultimate Guide

In the intricate machinery of industries, roller chains play an indispensable role in transmitting power and motion. However, just like any other mechanical part, roller chains undergo wear and tear over time. This is where the importance of chain wear measurement, timely sprocket replacement & proper maintenance comes into play.

Understanding Chain Wear: A Guide to Prolonging the Lifespan of Your Industrial Roller Chains

In the intricate machinery of industries, roller chains play an indispensable role in transmitting power and motion. These unassuming yet robust components are used in a wide array of applications, ranging from manufacturing and construction to transportation & agriculture. However, just like any other mechanical part, roller chains undergo wear and tear over time. This is where the importance of chain wear measurement, timely sprocket replacement & proper maintenance comes into play. In this article, we will delve into the world of chain wear, its implications, and how investing in wear gauges, sprockets, connecting links, and industrial roller chains can significantly extend the longevity of your machinery.

Understanding Chain Wear

Chain wear occurs due to the friction and stress imposed on the chain links as they engage with the sprockets. This wear can lead to elongation of the chain, causing it to no longer fit perfectly on the sprocket teeth. As the chain elongates, the pitch between the links increases, resulting in imprecise power transmission, reduced efficiency, and an increased likelihood of chain failure. Additionally, elongated chains can lead to accelerated wear on sprocket teeth, compounding the problem further.

Implications of Chain Wear

Reduced Efficiency

Elongated chains cause a loss of precision in power transmission, leading to decreased efficiency in machinery operations. This can result in higher energy consumption and decreased overall productivity.

Increased Downtime

A chain failure due to wear can lead to unexpected downtime, which can be costly in terms of both lost production time and potential repairs.

Safety Concerns

A worn-out chain poses safety risks to both equipment and personnel. Sudden chain failure could lead to accidents, injuries, or damage to surrounding equipment.

Higher Maintenance Costs

Neglecting chain wear can lead to a ripple effect of damage, causing not only the chain to fail but also impacting sprockets and other interconnected components. This translates to higher maintenance and replacement costs.

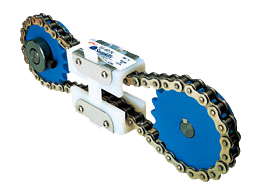

The Role of Wear Gauges

Wear gauges are essential tools for assessing chain elongation accurately. By measuring the distance between a certain number of chain pins over a specified length, wear gauges can determine the extent of elongation and help you decide whether it’s time for replacement. These gauges are easy to use and can prevent the costly consequences of neglecting chain wear.

Sprockets & Connecting Links

Sprockets are the counterpart to roller chains, and they work together to ensure smooth power transmission. When replacing a worn chain, it’s crucial to inspect and replace sprockets as well. Worn sprockets can accelerate chain wear and lead to premature chain failure. By investing in high-quality sprockets, you ensure the longevity of both the chain and the sprockets, optimizing the performance of your machinery.

Connecting links, or master links, are another critical component. These links enable the chain to form a continuous loop. When replacing a chain, using a connecting link that matches the specifications of your chain is vital for maintaining structural integrity and operational efficiency.

Maintenance Tips

Regular Inspection

Schedule routine inspections to identify signs of wear, such as elongation, corrosion, and worn sprocket teeth.

Lubrication

Proper lubrication reduces friction and wear, extending the life of your chain and sprockets.

Tension Adjustment

Maintain the correct tension in your chain to prevent excessive stress on both the chain and sprockets.

Environment Consideration

Be mindful of the operating environment, as harsh conditions can accelerate wear. Consider using specialized chains for extreme conditions.

In the intricate choreography of industrial machinery, roller chains are the unsung heroes that keep operations running smoothly. Understanding and addressing chain wear is paramount to maintaining efficiency, safety, and cost-effectiveness. By investing in wear gauges, high-quality sprockets, and proper maintenance practices, you can significantly extend the lifespan of your industrial roller chains, reduce downtime, and ensure the continued success of your operations. Don’t wait for unexpected failures to disrupt your workflow—take proactive steps to preserve the integrity of your machinery.

Related Products