OPTIME C1 – The World’s First Smart Lubricator

Turn Complexity Into Simplicity

OPTIME products are intrinsically safe and suitable for hazardous area applications.

Introducing the world’s first truly smart lubricator…

The world is complex. And part of that complexity comes from truly insignificant things: the tasks you would like to cut out of your daily maintenance routines – but can’t. Such as lubricating by hand. Such as manually checking on the condition of the many lubricators throughout your plant. Such as finding the best lubrication parameters for your automatic lubricators. Such as fixing the 80% of premature bearing failures related to lubrication problems. And there has been simply no better way of doing these tasks – up to now at least. With Schaeffler’s OPTIME C1, you can simplify the task of lubricating your machines. Combining all the benefits of our C1 automatic lubricators with award-winning condition monitoring technology: The OPTIME C1 turns complexity into simplicity.

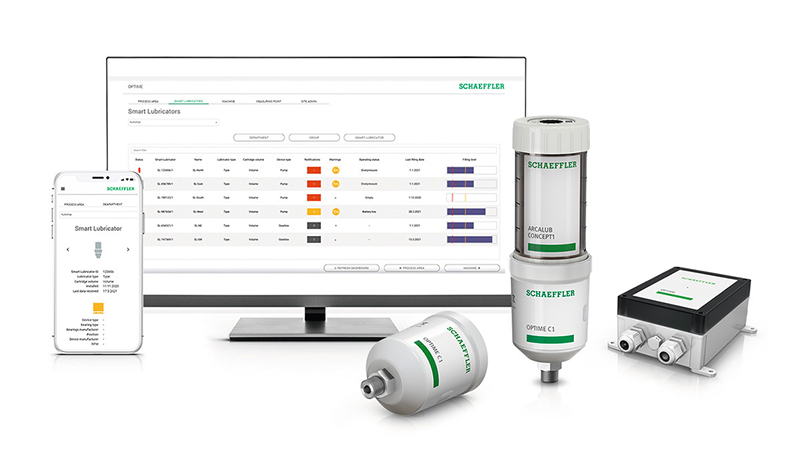

We are proud to present the world’s first smart lubricator, a system that streamlines lubrication management via alerts from a mobile app or web-based dashboard – letting you know exactly when a lubrication point needs your attention.

OPTIME C1 Features

- NFC, giving you plug and play capability

- Mesh communication, facilitating a robust, easily manageable network

- Replaceable battery

- Increased pressure (up to 10 bar) via an electrical pump

Concept1 cartridge

- OPTIME C1 is compatible with Concept1 cartridges

- Can be refilled with our ARCANOL high-performance, or your own alternative

Gateway

Mobile communication via SIM or Ethernet compatible

OPTIME digital service

Easy to use mobile app and powerful web-based dashboard for desktop PCs

Less Complexity, Less Manual Work, and Less Downtime – Produce More Benefits.

More Transparency

Thanks to our industry-leading technology, you just need to check the mobile app to check on the status of your lubricators – however many there are, from wherever you are. It’s as simple as that.

More Simplicity

Simplicity is the name of the game when it comes to the OPTIME C1. It’s simple to install, use and refill. You will then have more time to concentrate on more pressing tasks.

More Uptime

The OPTIME C1 eliminates premature bearing failure caused by insufficient and/or incorrect lubrication – thus eliminating unexpected, unwanted and costly machine downtime.

Three Unique Challenges – And How the OPTIME C1 Can Help You Overcome Them

Challenge 1: You have hundreds of lubrication points to manage

Maintain an overview of the filling levels of each of your lubricators and any potential lubrication problems – no matter where you are – by connecting them to the Industrial Internet of Things (IIoT).

Challenge 2: You need to change the lubricator cartridge

Reduce costly manual mistakes when changing your lubricator cartridge with the OPTIME app, which will inform you about the appropriate grease to use and the correct settings for that specific lubricator.

Challenge 3: You want to get started – but don’t know how?

Connect your OPTIME C1 lubricators quickly and simply thanks to their plug-and-play functionality and the extremely user-friendly OPTIME app.

Customer Success Story

The smart functionality in the device will simply warn you of any impending lubrication shortage, saving you time and money.

Read Schaeffler’s customer success story to see how they helped a long-running German industrial company, enabling it to avoid mill failures and preventing €47,000 worth of damages, all in a factory environment where components operate at up to 1,200°C.

Learn even more about the OPTIME C1

Our video explaination may help answer any final questions.

From the way you will interact with OPTIME C1, to its main benefits – our ‘how-to-video’ will help you answer any final questions you have about our state-of-the-art solution.

If you would like to learn more about OPTIME C1, then please read our solution description to get all the technical specifications you need.

Learn about the OPTIME C1’s technical specifications